Description

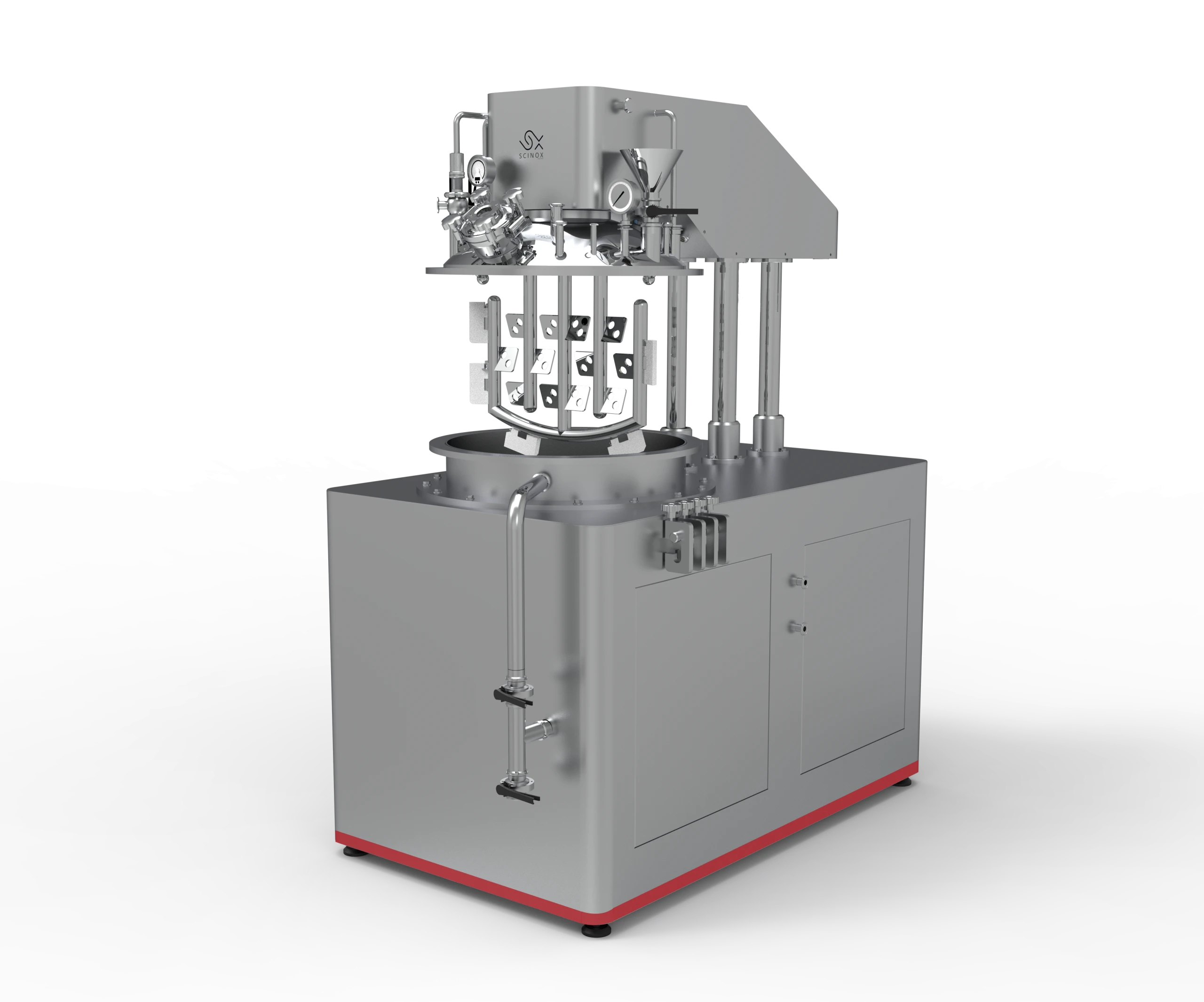

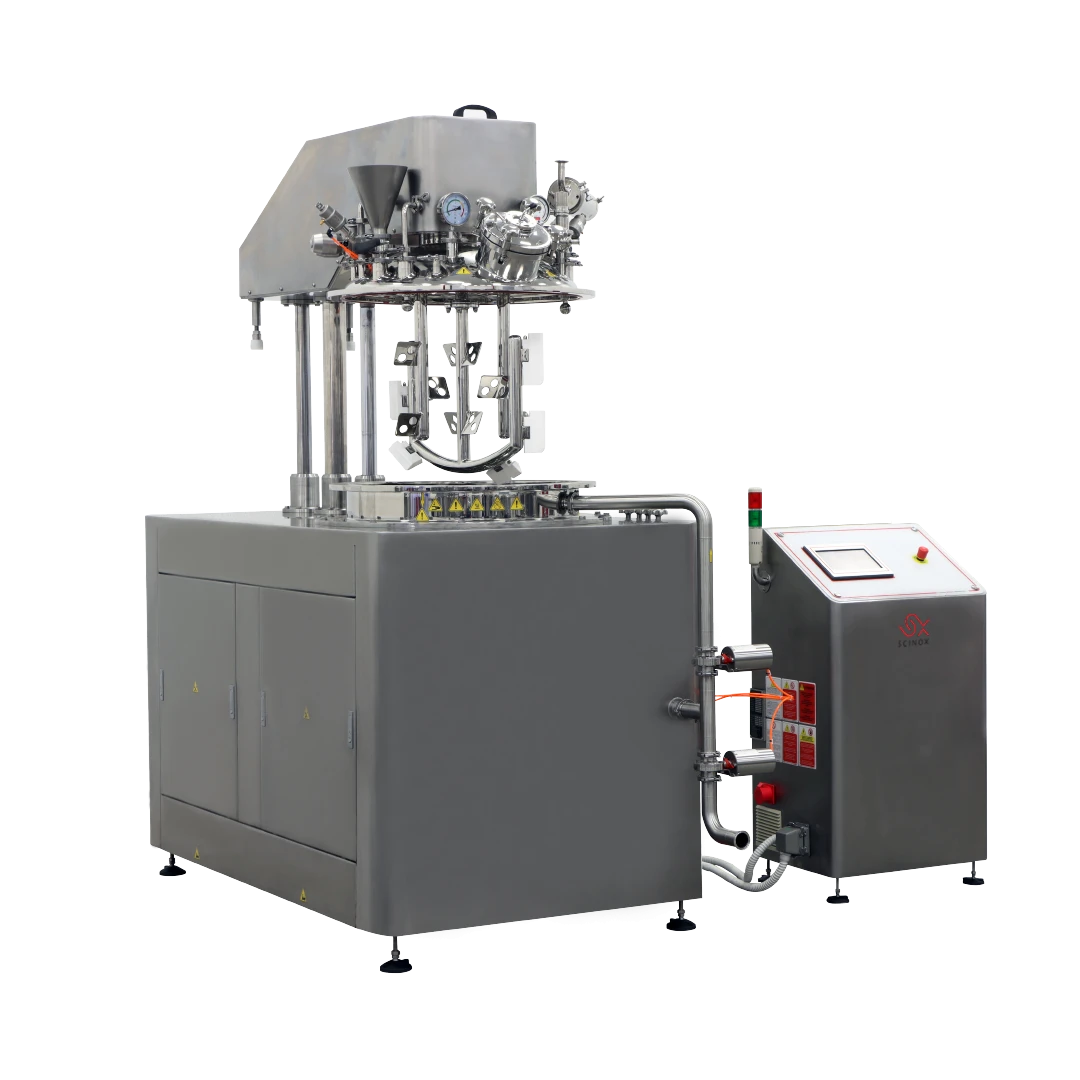

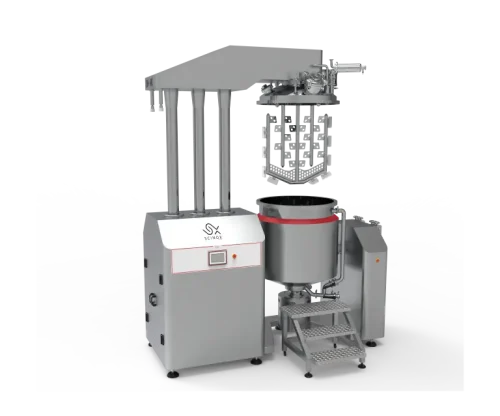

Pro Mixer’s main parts:

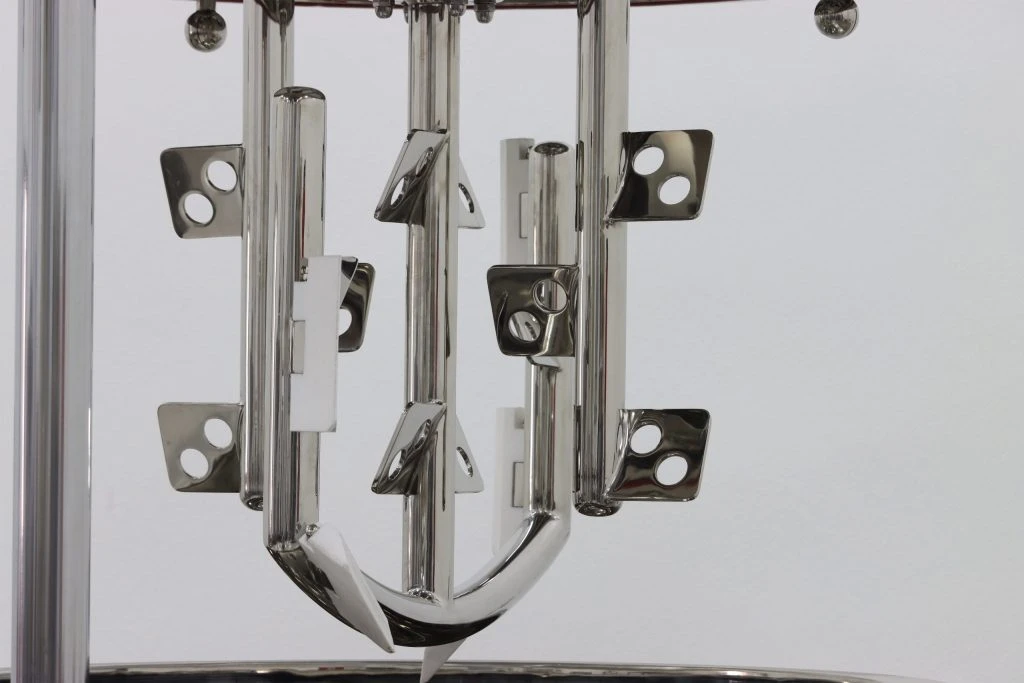

- Mixer’s cover: Equipped with an Anchor mixing mechanism.

- Mixer’s chamber : Equipped with Safety valve and pressure Gauge for double-jacket.

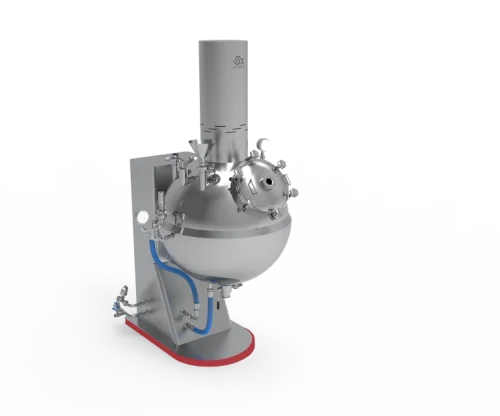

- Mixer’s bottom : Equipped with a special designed homogenizer.

- Mixer’s base :

- Vacuum system

- Clean in place system CIP.

- A hydraulic system equipped with all the necessary protections for mixer’s cover Vertical movement.

- PLC & HMI Control panel to control all operation functions of Pro Mixer.