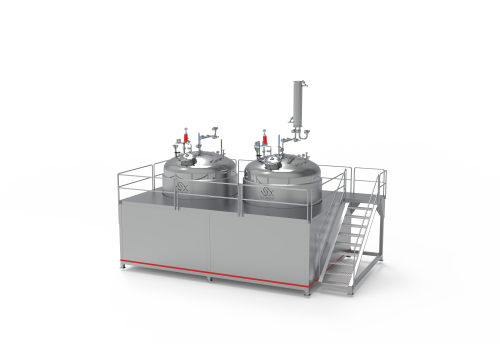

Description

• Storage tank: insulated with rock wool

- Tank’s head equipped with:

-

- VENT filter & silicone heating jacket.

- Mechanical diaphragm pressure gauge.

- Tank’s body equipped with:

-

- Manually controlled Aseptic valve for sampling.

- PT100 temperature sensor to read and control the temperature.

- Tank’s Bottom equipped with:

-

- PT100 temperature sensor to read and control the temperature.

- Product transporting & circulation outlet.

- Drainage outlet.