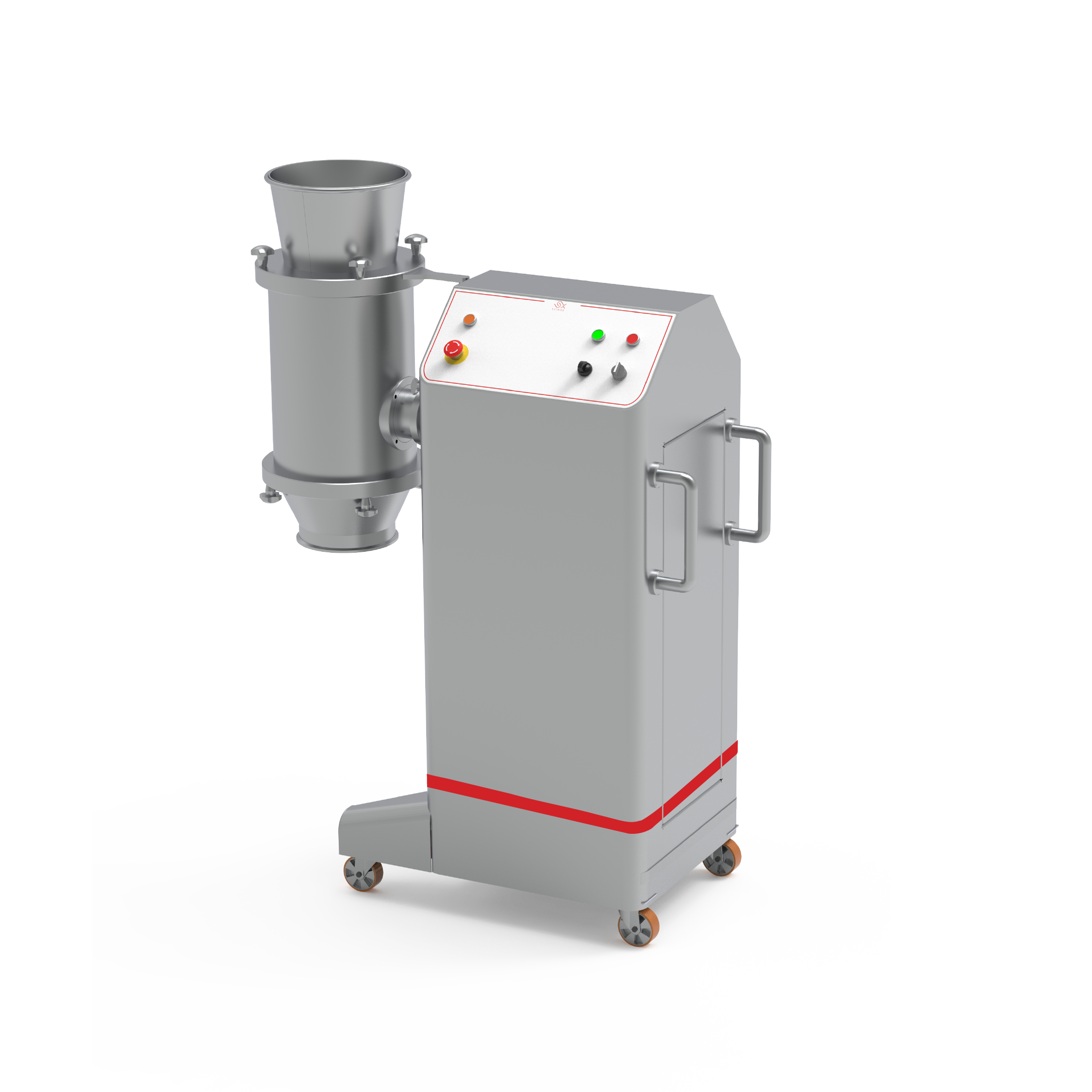

Description

Wet Powder Mill’s main parts :

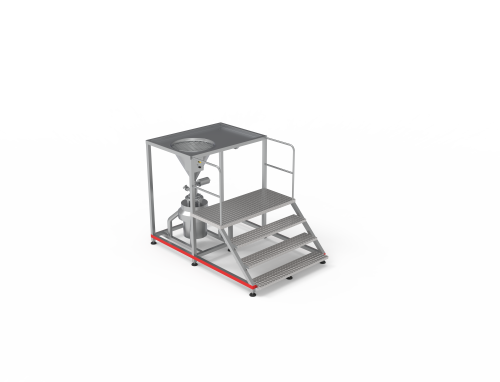

- A cylindrical agitation chamber equipped with:

– A product inlet through which the granules enter.

– A stainless steel cone screen.

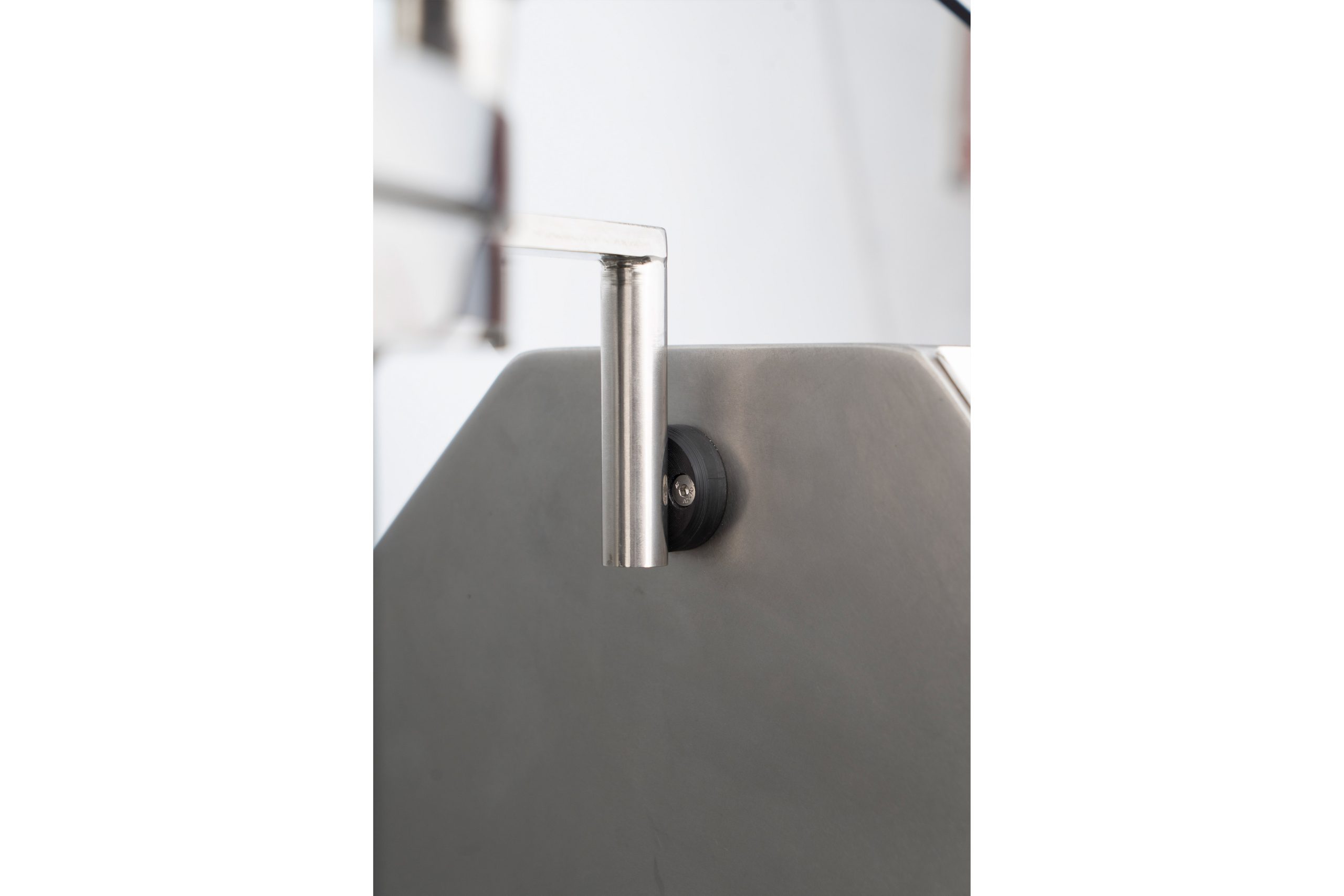

– A detachable, replaceable agitation mechanism driven by a motor and speed reducer.

– A granule discharge outlet. - The base is equipped with wheels for easy transport, housing the motor and speed reducer.