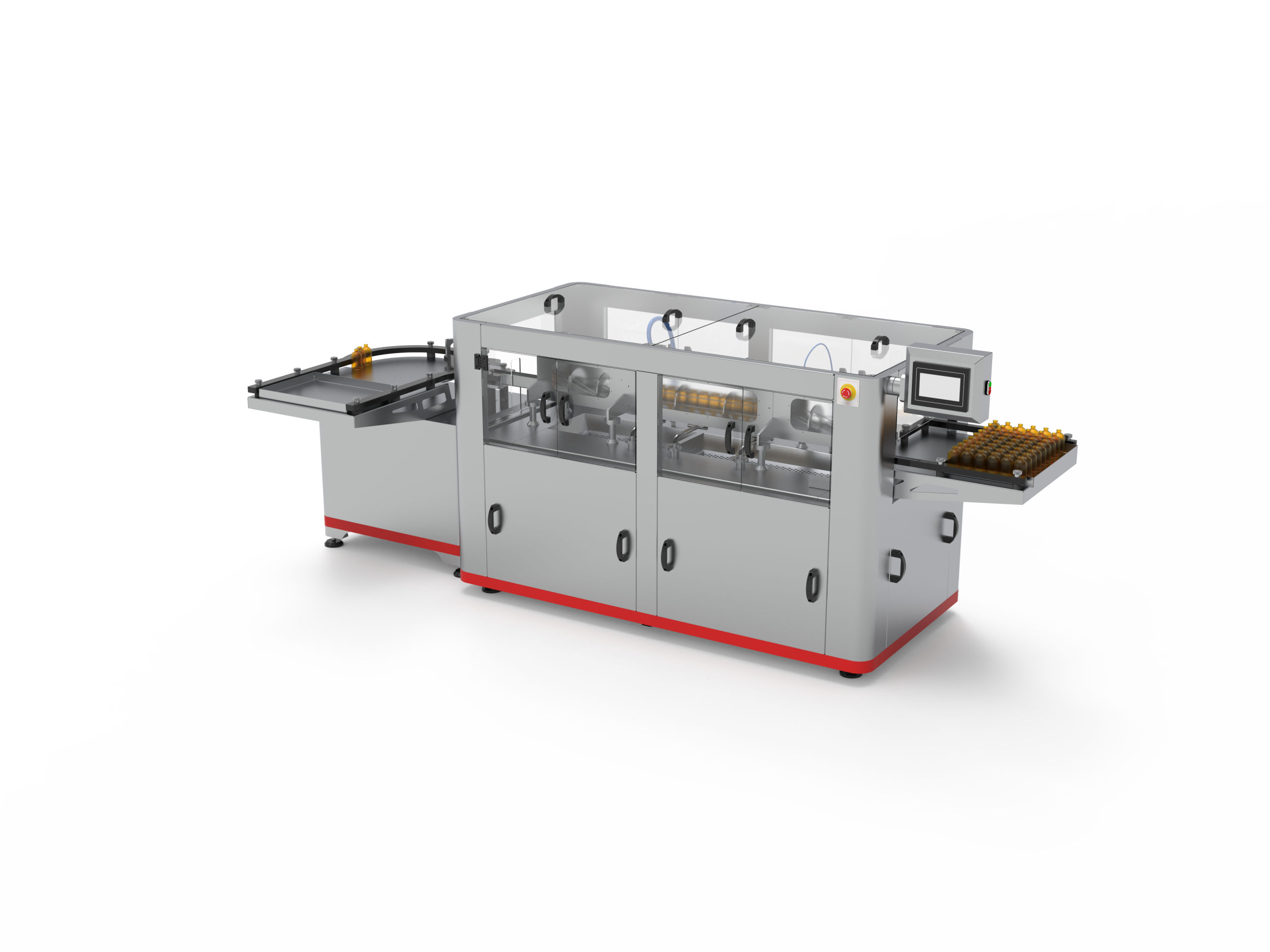

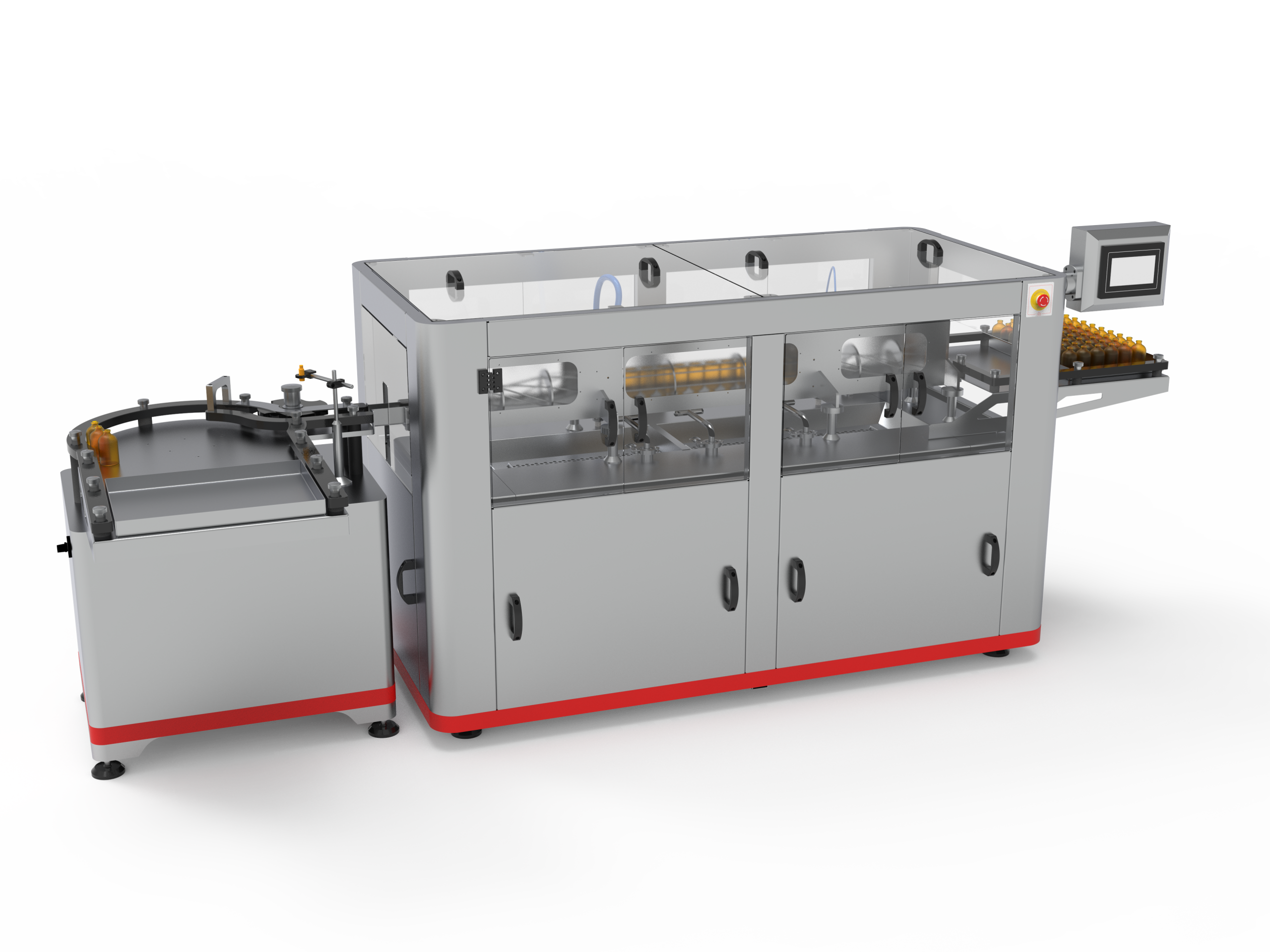

Description

Washing bottle continues’s main parts :

- External rotating feed tray: Receives and feeds the packages into the machine.

- First-stage package overturning mechanism.

- Internal and external package washing stage, consisting of:

-First stage (Pre-Washing): Two heads for pumping Pure Water (P.W).

-Second stage (Main Washing): Two heads for pumping Water for Injection (WFI).

-Third stage (Drying): Two heads for pumping Compressed Clean Air (C.C.A) into the packages, and two heads for air evacuation.

- Second-stage package overturning mechanism.

- Fixed receiving table: Receives the packages after all washing and drying stages are completed.