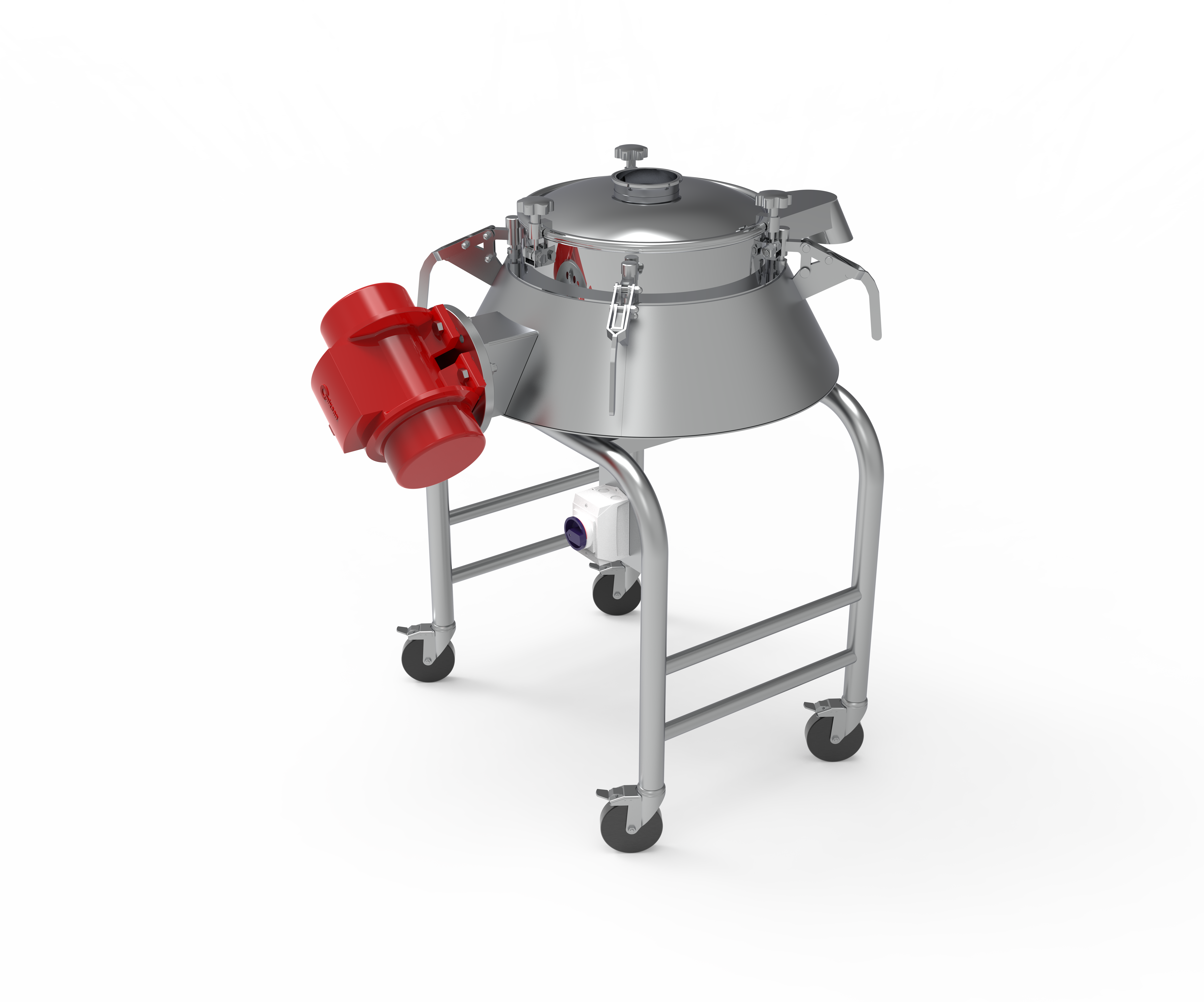

Vibrating sieve

- Vibrating sieve is part of our wide range of powder machines .

- It is considered one of the essential equipment in the pharmaceutical, food and chemical industries

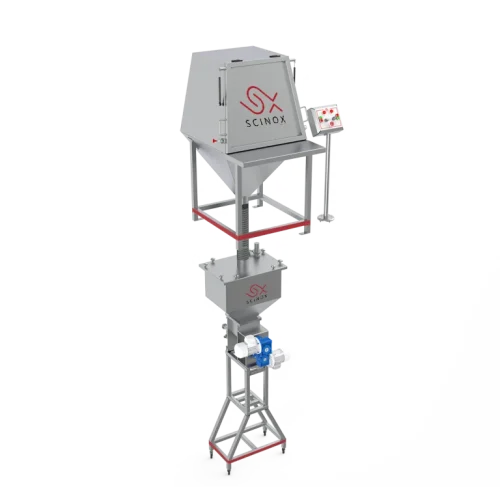

- It is used to sort raw materials (sifting dry powder), separate and dispose of impurities, and prepare materials for production processes

- The materials to be sieved are entered through a central opening, so that the sorting process takes place through a single stage, and then the materials (powder) are exited through a discharge opening at the bottom of the sieve.

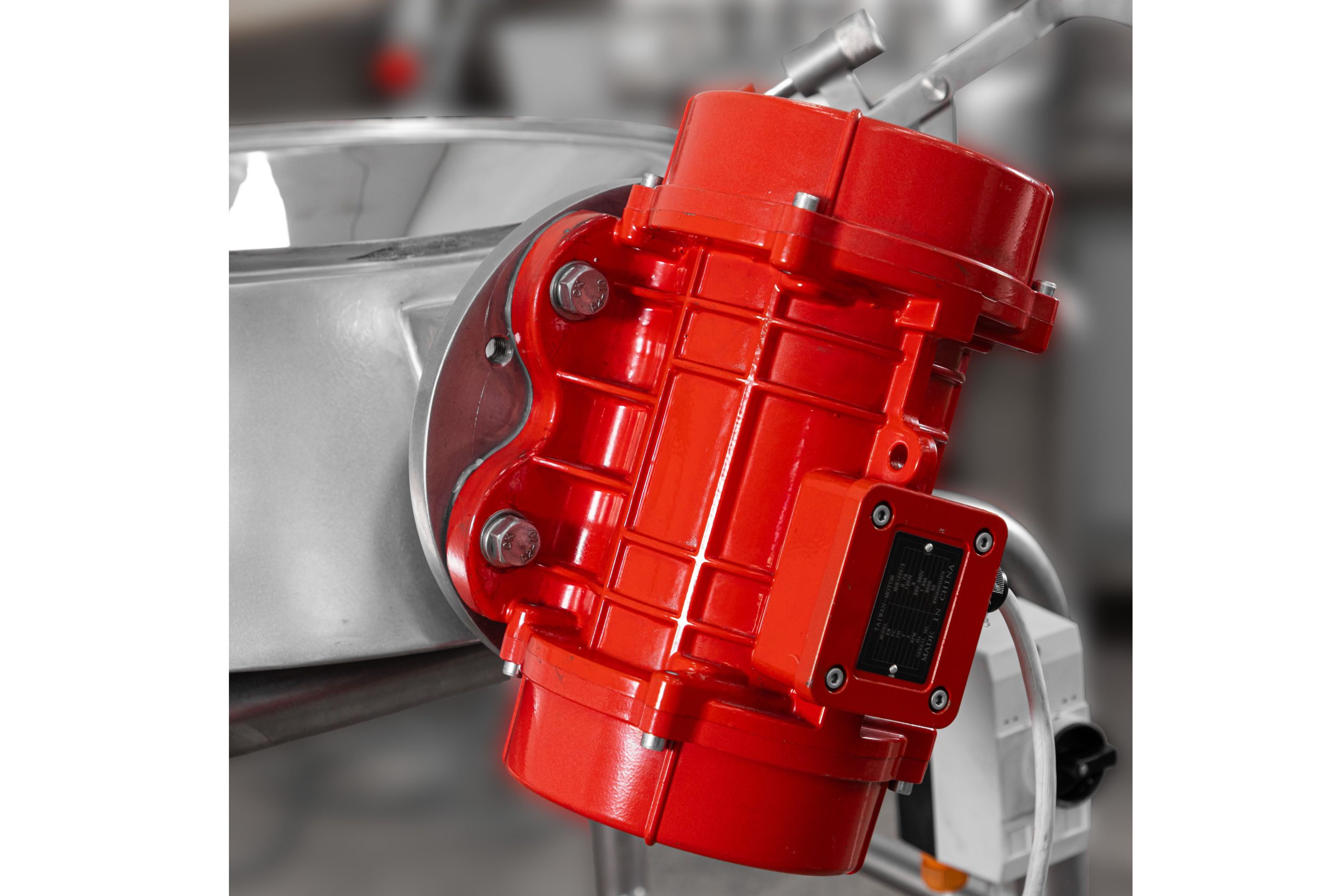

- All points welded by TIG & ORBITAL polished and treated.

- The parts that are in contact with materials are made of stainless steel (316), while the parts that are not in contact with materials are made of stainless steel (304), resistant plastic and treated aluminum.

- Interior surface of the Vibrating sieve is a mirror finishing and exterior surface is a Matt finishing .

Description

- Top section , Equipped with:

A circular cover mechanically polished with a mirror, sealed with a silicone gasket, intended for the supervision and cleaning process

equipped with a central opening through which the product to be sifted enters.

- Sieve body, It includes the product sieving process, equipped with:

-Engine block.

– Approximately sieve, single stage diameter.

– Side channel through which impurities exit and are disposed of.

-Removable and removable mounting clips for mounting the sieve for easy replacement and cleaning.

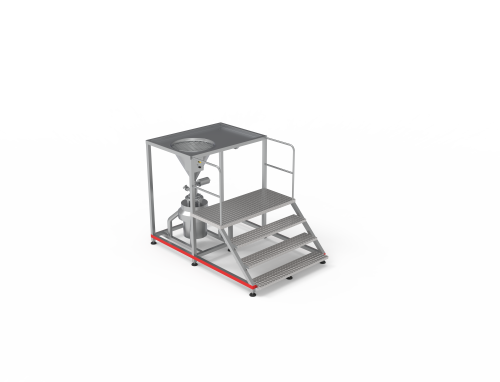

- Bottom section:

Mounted on a wheeled base for easy movement, the sieve body is supported by flexible rubber springs

equipped with an opening with a clamp for discharging the product.

Technical Data

- Vibrating sieve featured by high efficiency, ease of use and low maintenance.

- The sieve is designed and manufactured in accordance with international quality systems

- The sieve can be designed to meet exact customer requirements.

- Documentation and protocols ( DQ–IQ–OQ–FAT–SAT).

- After-sales services include maintenance operations and constant availability of spare parts.