Description

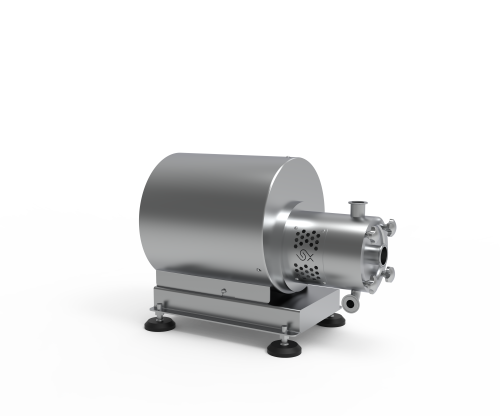

Vertical homogenizer ‘s main parts:

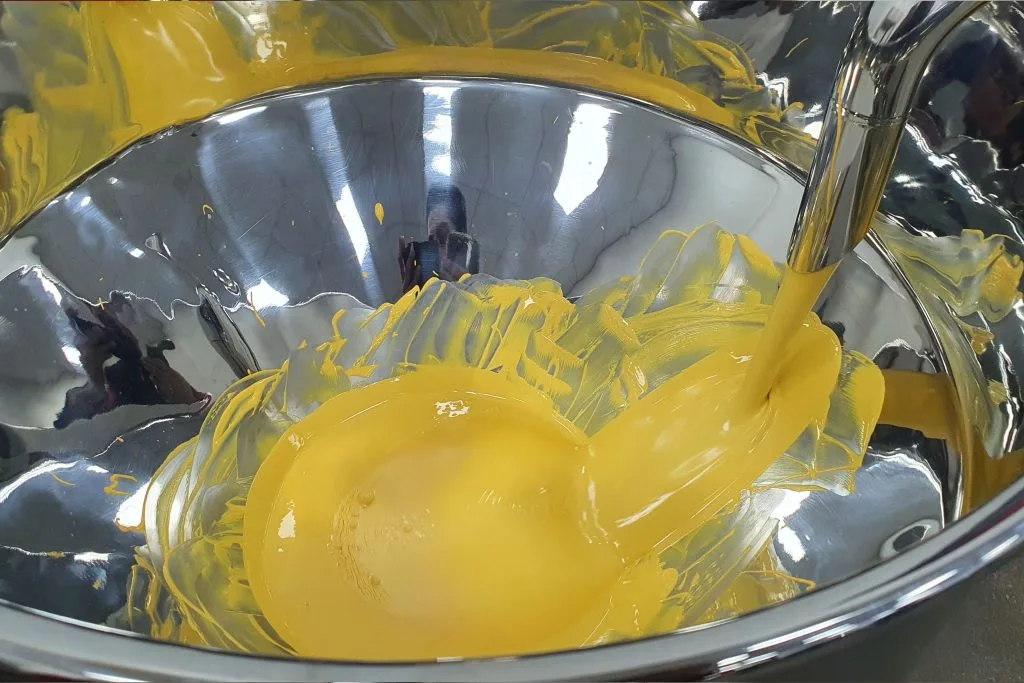

- Homogenization chamber.

- Homogenizing head that consists of two parts:

-

- Rotor to perform the process of withdrawing and pushing the product.

- Stator to perform the process of homogenizing and softening.

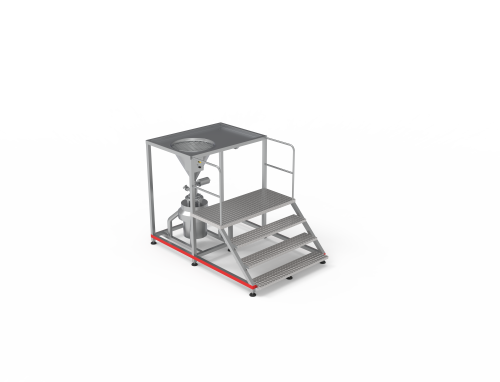

- Homogenizing chamber that equipped with two outlets:

-

- The first outlet is to recycle the product during work.

- The second outlet is to discharge the product via a manual control valve.

- Drain port designated for CIP process.