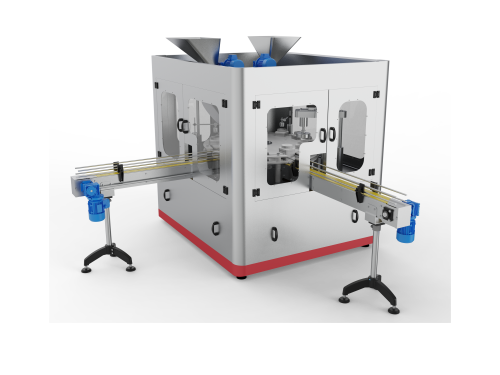

Description

Pro-Aseptic powder filling Machine’s main parts:

- A fixed table to receive vials from the Previous sterilization stage.

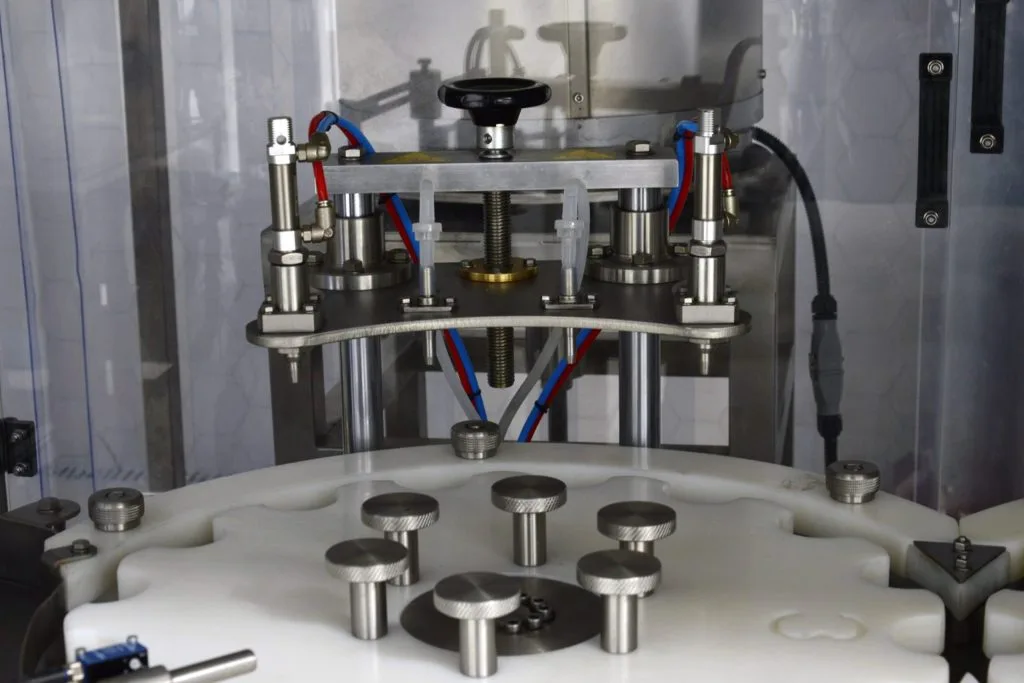

- Rotating tray .

- Rotating star: equipped with Container centers.

- Nitrogen pump head- stage 1

- Balance tank with level sensor and VENT bacterial filter to ensure a continuous and regular flow of preparations during the filling process.

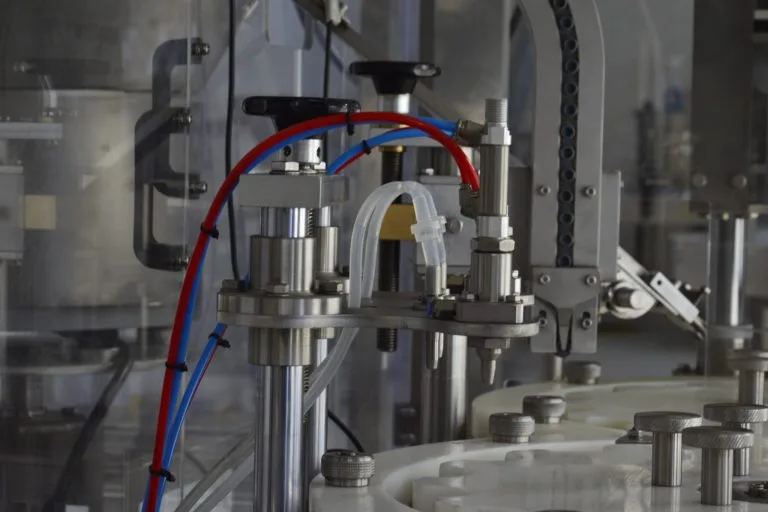

- Filling head via a peristaltic pump (silicone treated with Platinum tube pump) and the filling range can be calibrated via the LCD screen.

- Packaging takes place in two stages per vial to increase production capacity and save time.

- Nitrogen pump head- stage 2

- Rubber seal feeder.

- Metal cap feeder.

- Metal lid closing mechanism

- Conveyor belt for ejecting the vials :Driven by a motor and speed reducer encased in a stainless steel cover in accordance with cGMP requirements