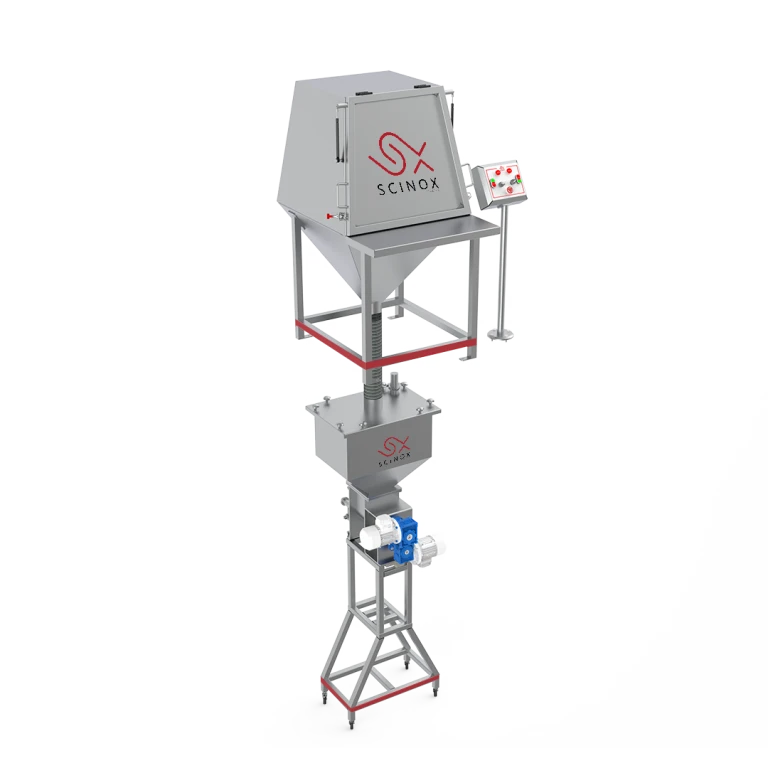

Powder Micro Dosing

- Powder Micro Dosing is part of our wide range of powder machine.

- It is considered one of the basic equipment in the food and chemical industries.

- As it’s used to receive the product (powder) from the raw material bags and transfer it to the Micro Dosing. The unit is equipped with a protective net and a (Hood) system connected to the (Dust Free) system to keep the production hall free of dust.

- All welds are welded by TIG & ORBITAL and polished and treated.

- It’s made of stainless steel (304) for the parts in contact with the materials and those not in contact with the materials.

- The unit is mechanically polished from the outside to a smooth ,from the inside to a smooth mirror .

Description

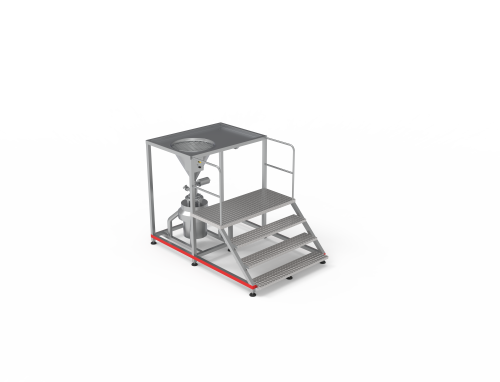

- Product bag receiving unit (powder), The unit consists of:

- Service table

- Corner cover

- Upper protection net.

- Hood system with Dust Collector system:

- Bottom discharge hole

- Capacitance suppression : It is equipped with a level measurement system and a vibration Shake System to prevent the product from sticking while discharging the product (powder) into the Micro Dosing.

- Micro Dosing

Technical Data

- Powder Micro Dosing featured by high efficiency, ease of use and low maintenance.

- It is designed and manufactured in accordance with international quality systems

- It can be designed to meet exact customer requirements.

- Documentation and protocols ( DQ–IQ–OQ–FAT–SAT).

- After-sales services include maintenance operations and constant availability of spare parts.