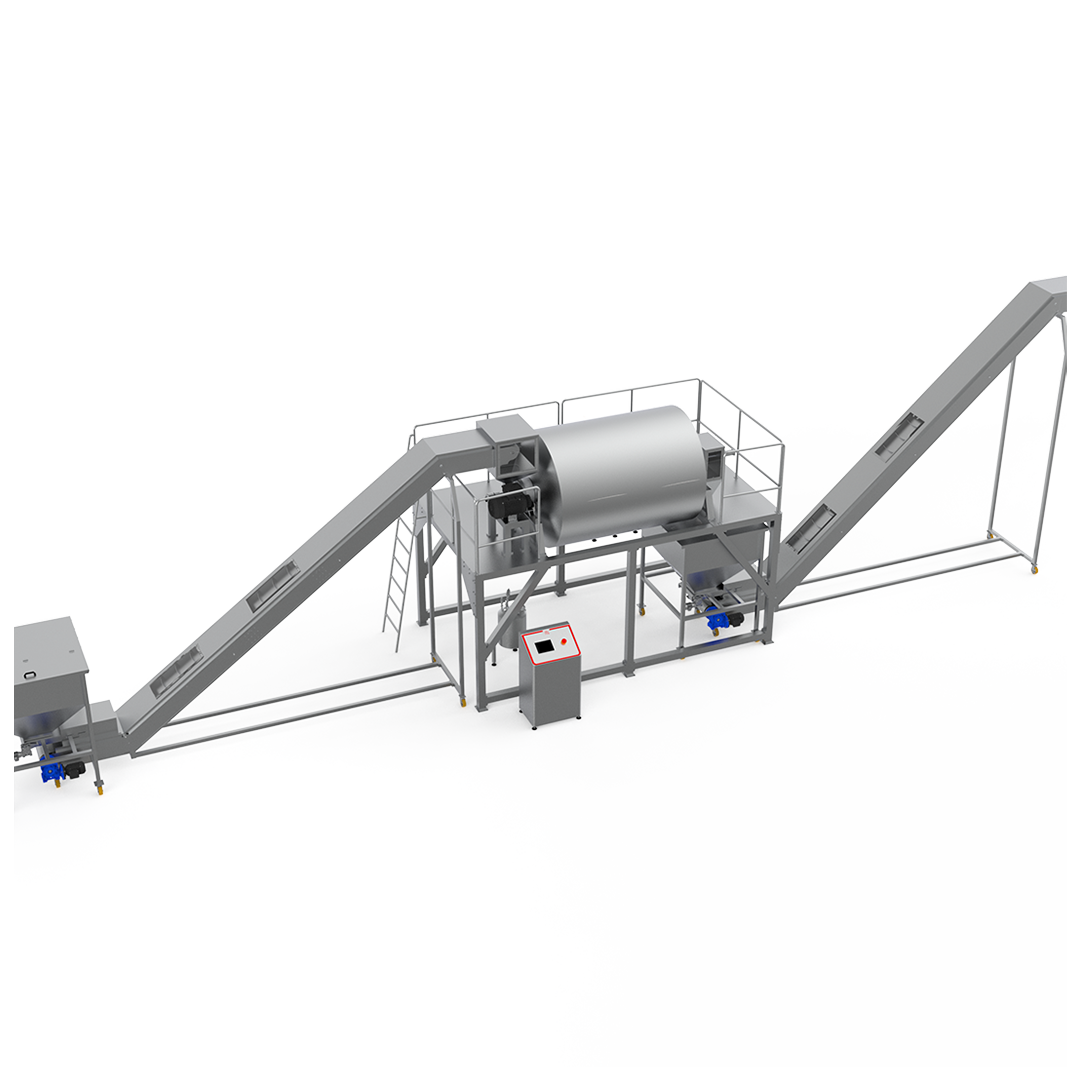

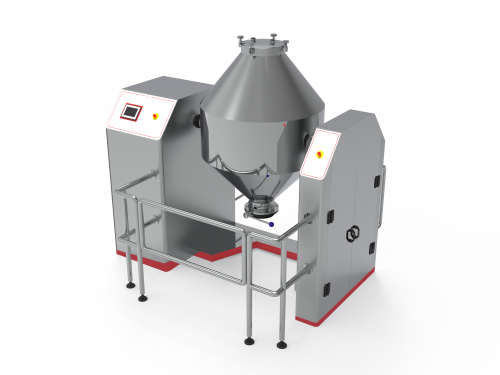

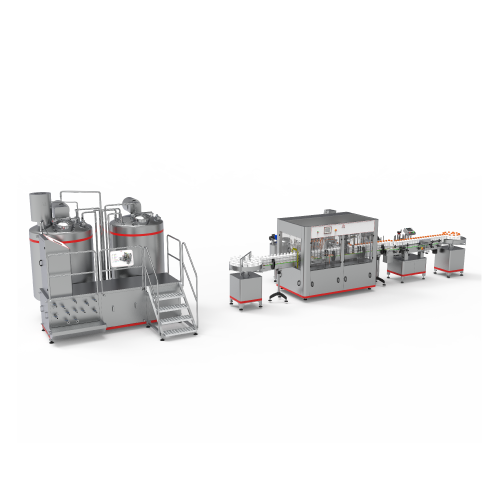

Powder detergent production line

- Is part of our wide range of powder mixers for mixing & homogenizing dry powder .

- It is considered one of the basic equipment in the chemical and food industries, as it is used to homogenize and mix fragile powders (washing powder, tea, coffee, frozen mixed vegetables, legumes, feed .. etc. ) It is characterized by distinctive mixing results and achieving high efficiency and high productivity.

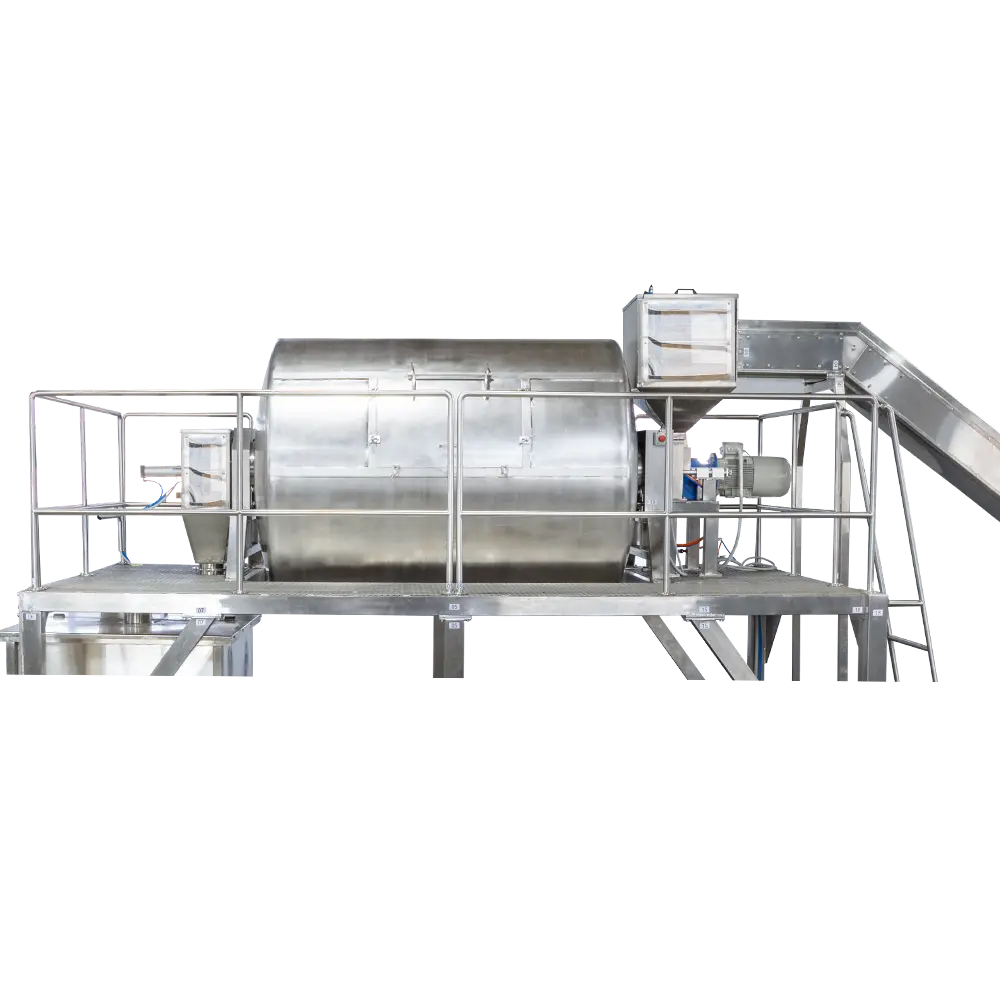

- all points welded by TIG & ORBITAL polished and treated

- Product contact parts made of SS (316 L) and non-contact parts made of SS ( 304 ).

- Interior & exterior surface of blender is a Matt finishing .

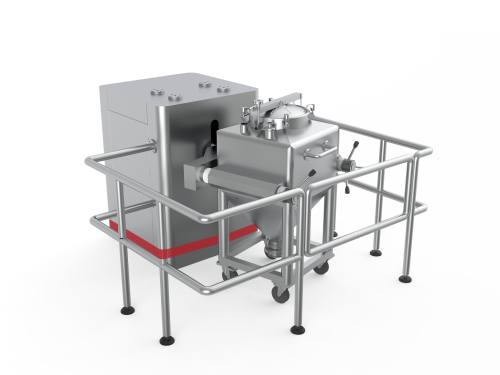

Description

- A basin that receives raw materials and passes them to the linear powder conveyor

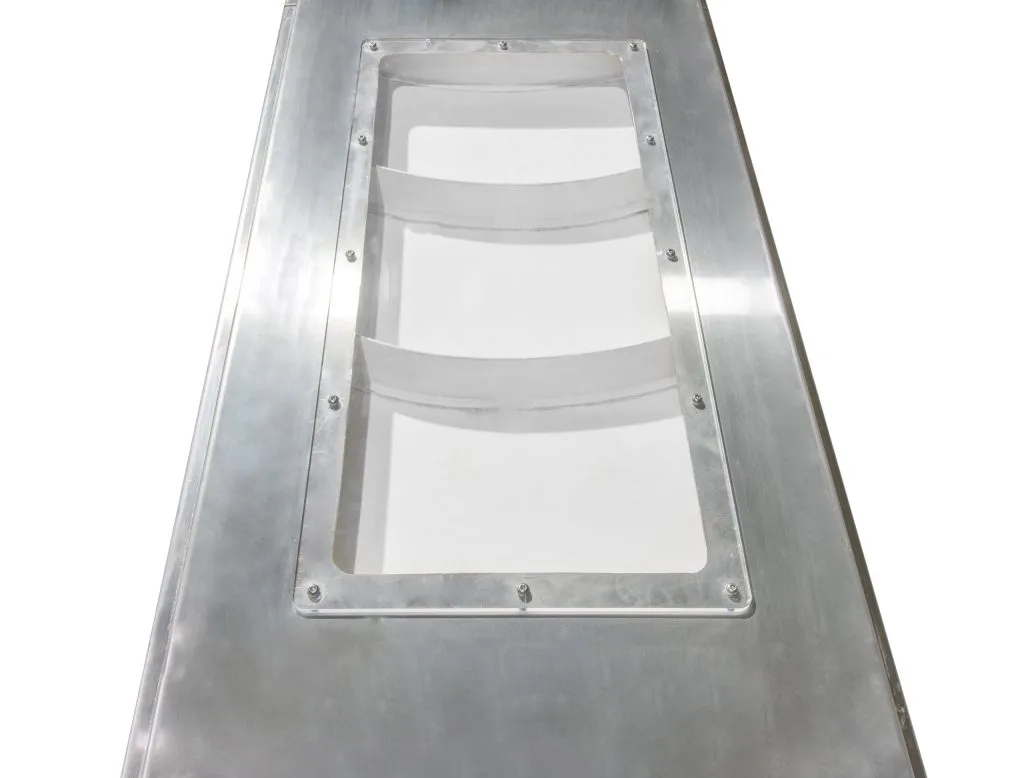

- the loading chamber equipped with a vision port that allows supervision and follow-up of the workflow.

- A rotating, horizontal, cylindrical mixing chamber equipped to distribute and mix the product without affecting its density in a regular and proportional manner to the process of receiving the products.

- where the mixing and filling processes take place continuously.

- The product receiving basin after completing the mixing process is placed under the unloading chamber

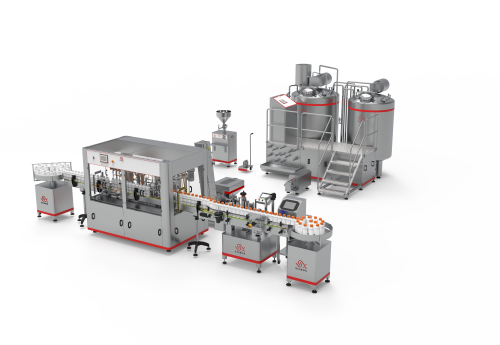

- and then to the linear powder conveyor linked to the filling machine.

Technical Data

- Drum Mixer featured by high efficiency, ease of use and low maintenance.

- The blender is designed and manufactured in accordance with international quality systems

-

| Model |

D.P.M 500 |

D.P.M 1000 |

D.P.M 2000 |

| Capacity / L |

500 |

1000 |

2000 |

- The production capacity varies depending on the type and density of the product.

- The blender can be designed to meet exact customer requirements.

- Documentation and protocols ( DQ–IQ–OQ–FAT–SAT).

- After-sales services include maintenance operations and constant availability of spare parts.