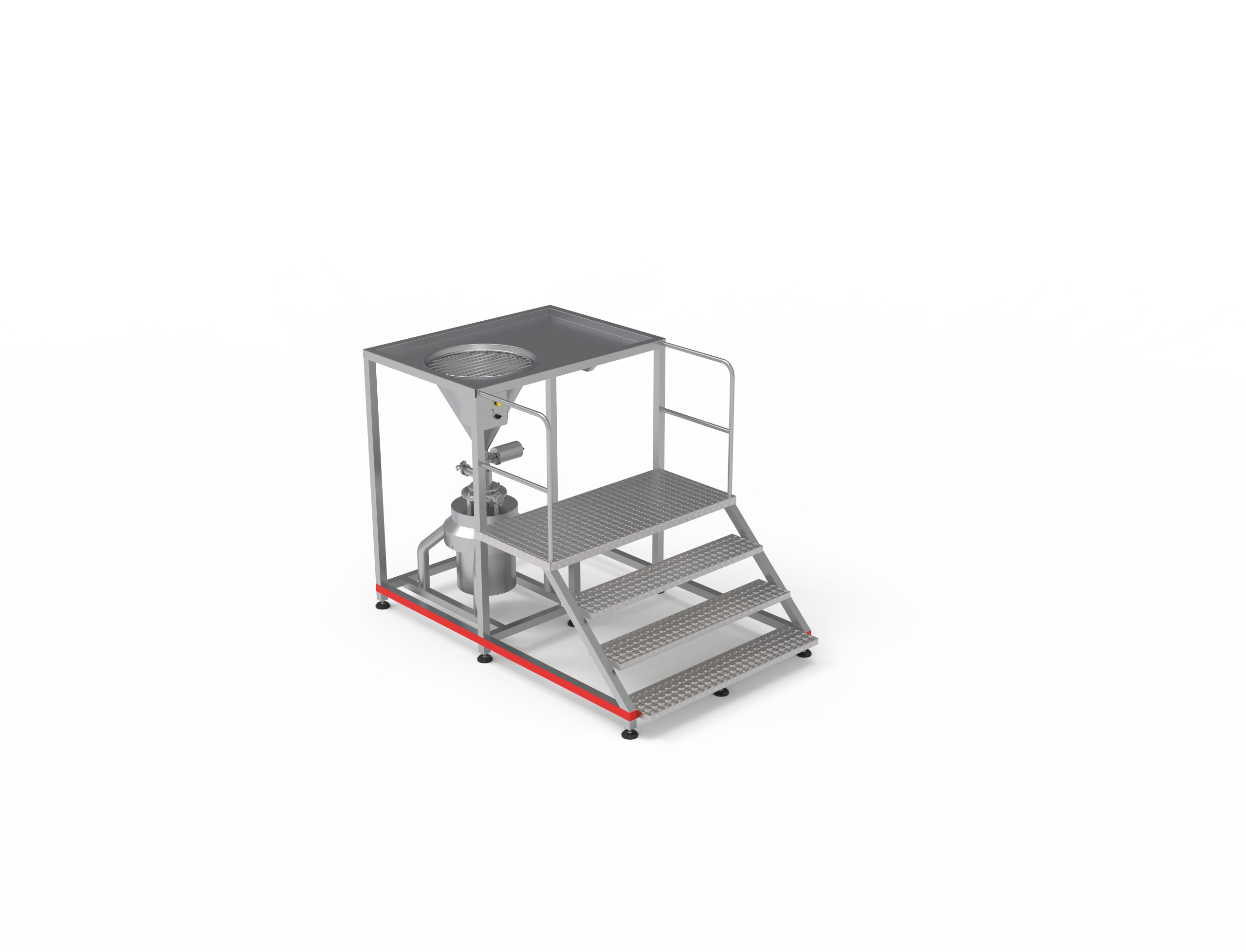

Description

Liquid & Powder Mixing Mechanism’s main parts:

- Conical funnel: equipped with a manual discharge valve installed at the bottom of the funnel as well as a vibration mechanism (optional) operated by compressed air to prevent the powder from sticking to the wall of the funnel.

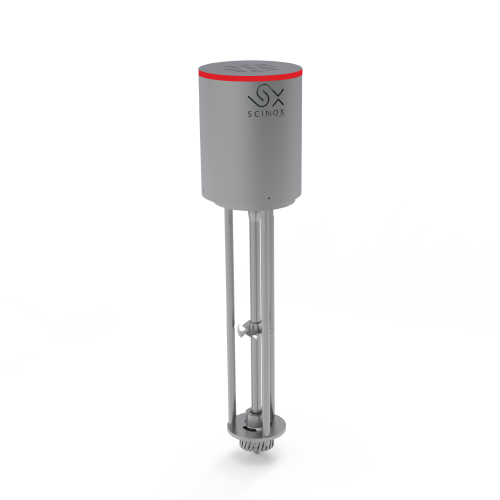

- Mixing head : located inside the mixing chamber and is driven by a motor & a cooling mechanical seal.