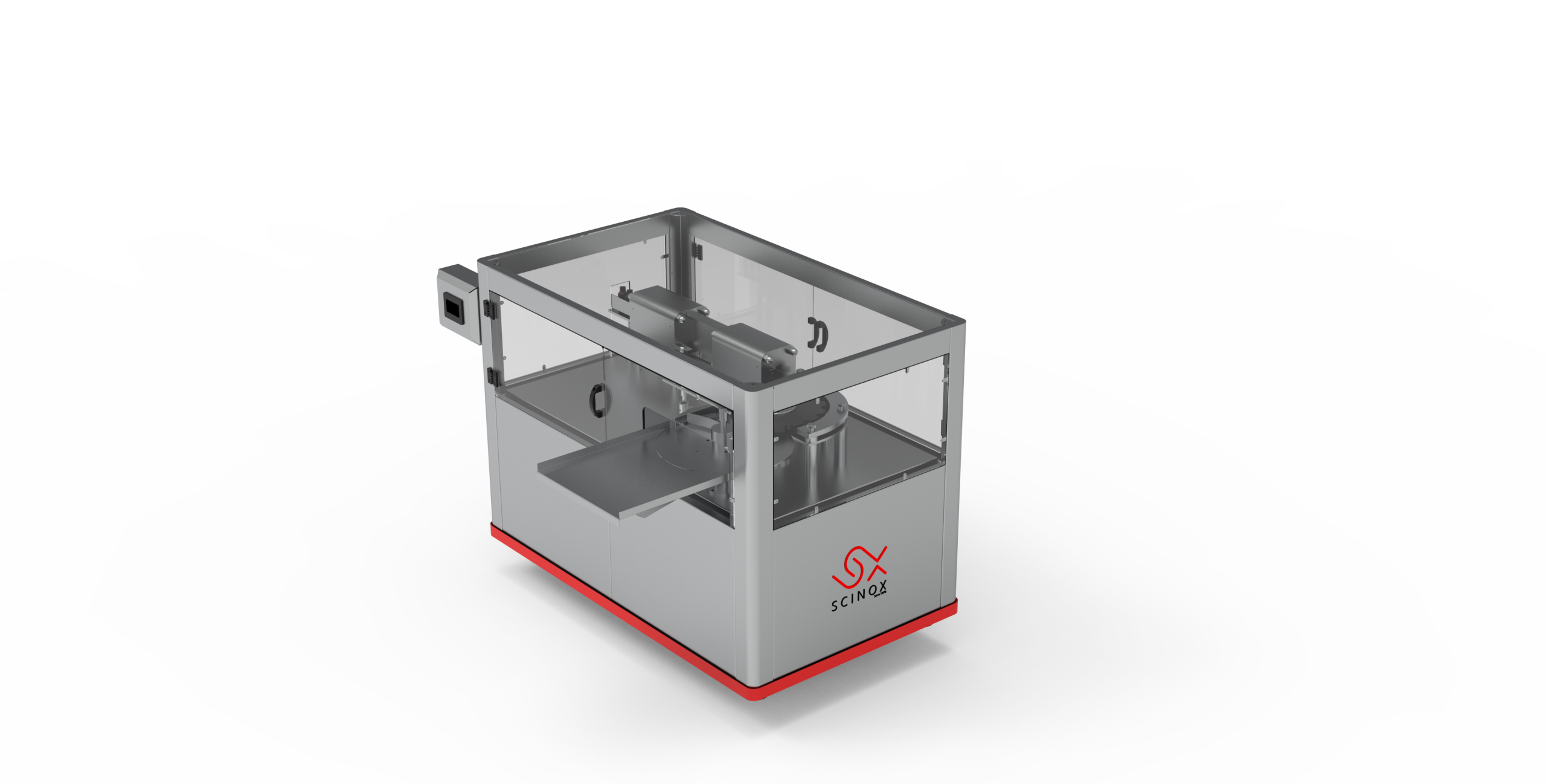

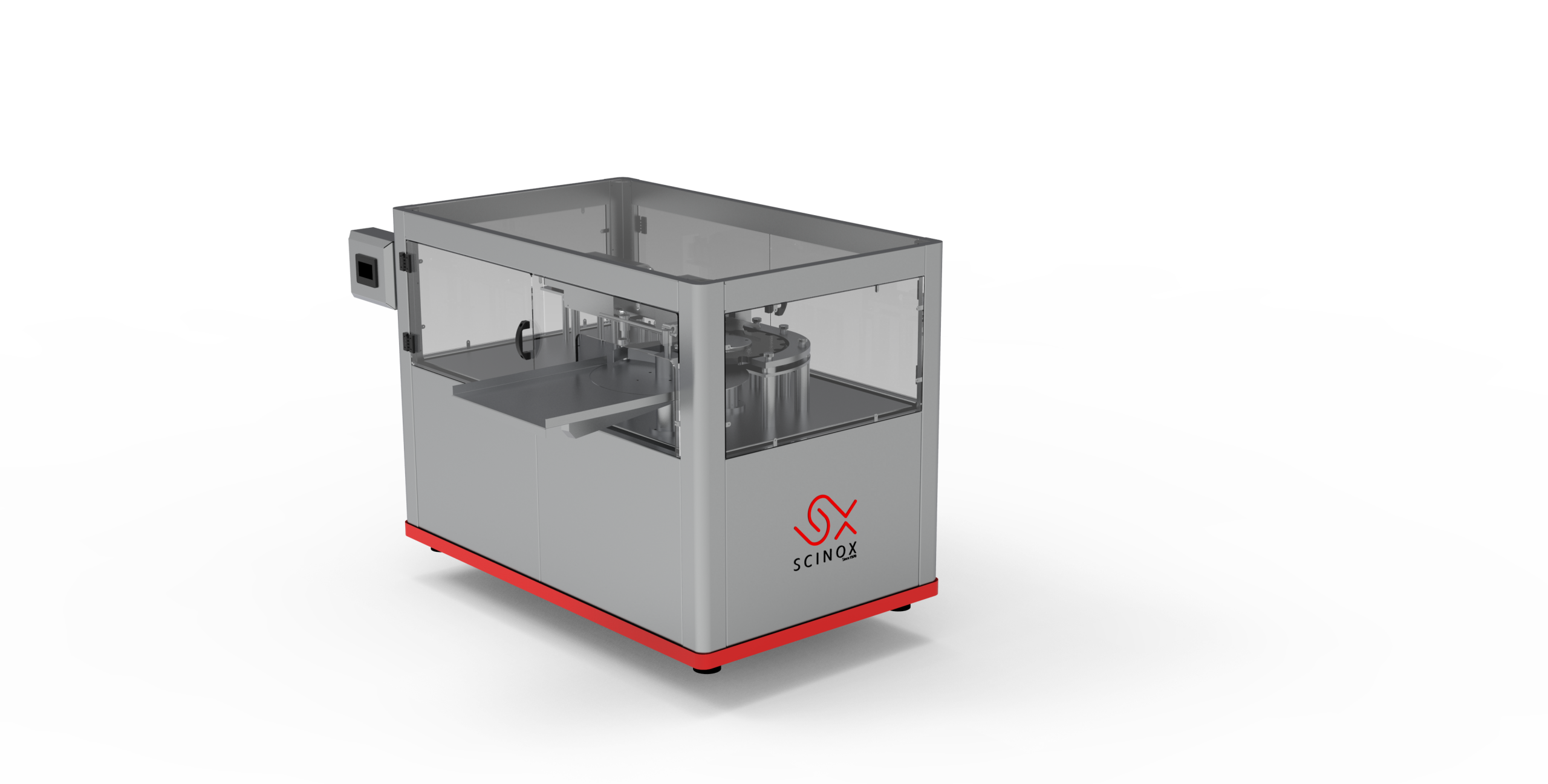

Description

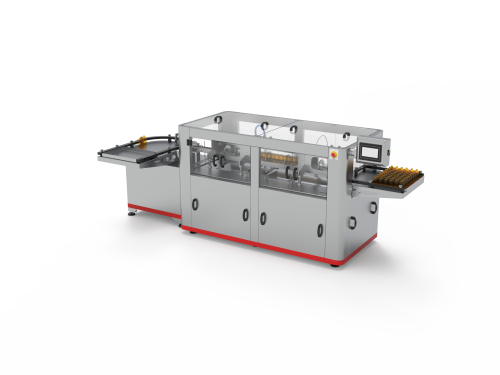

Blowing machine’s main parts :

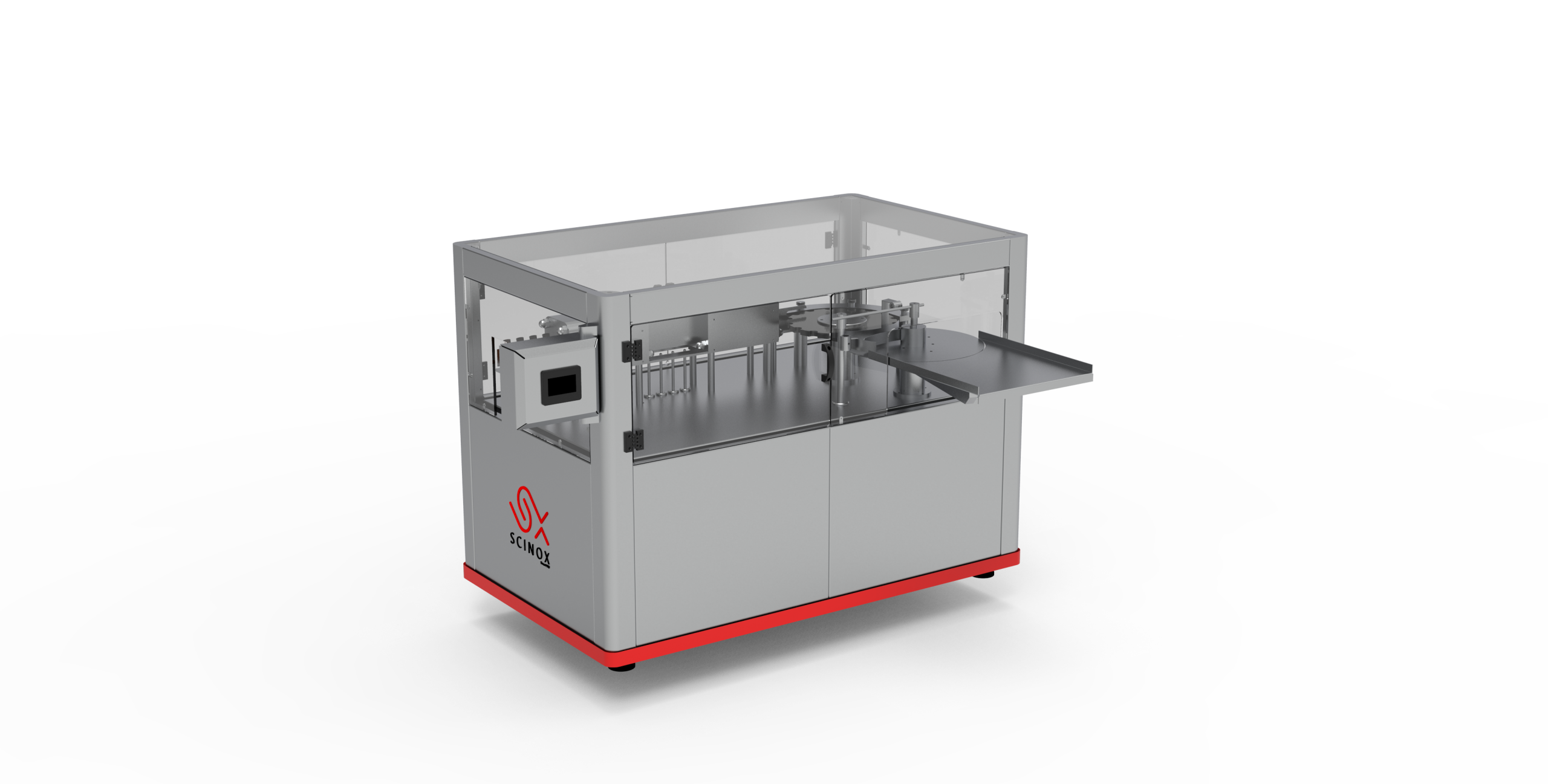

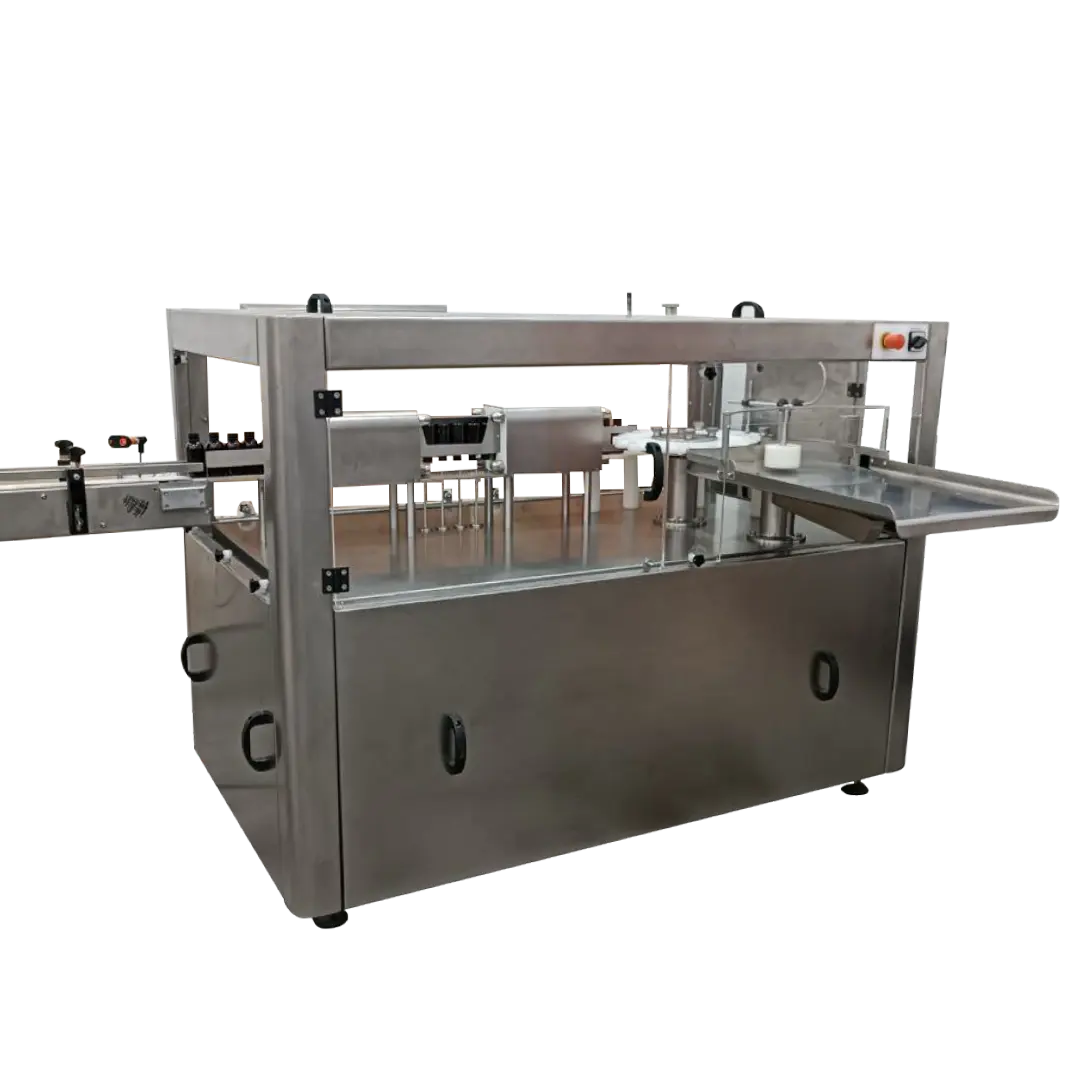

- A packages receiving table.

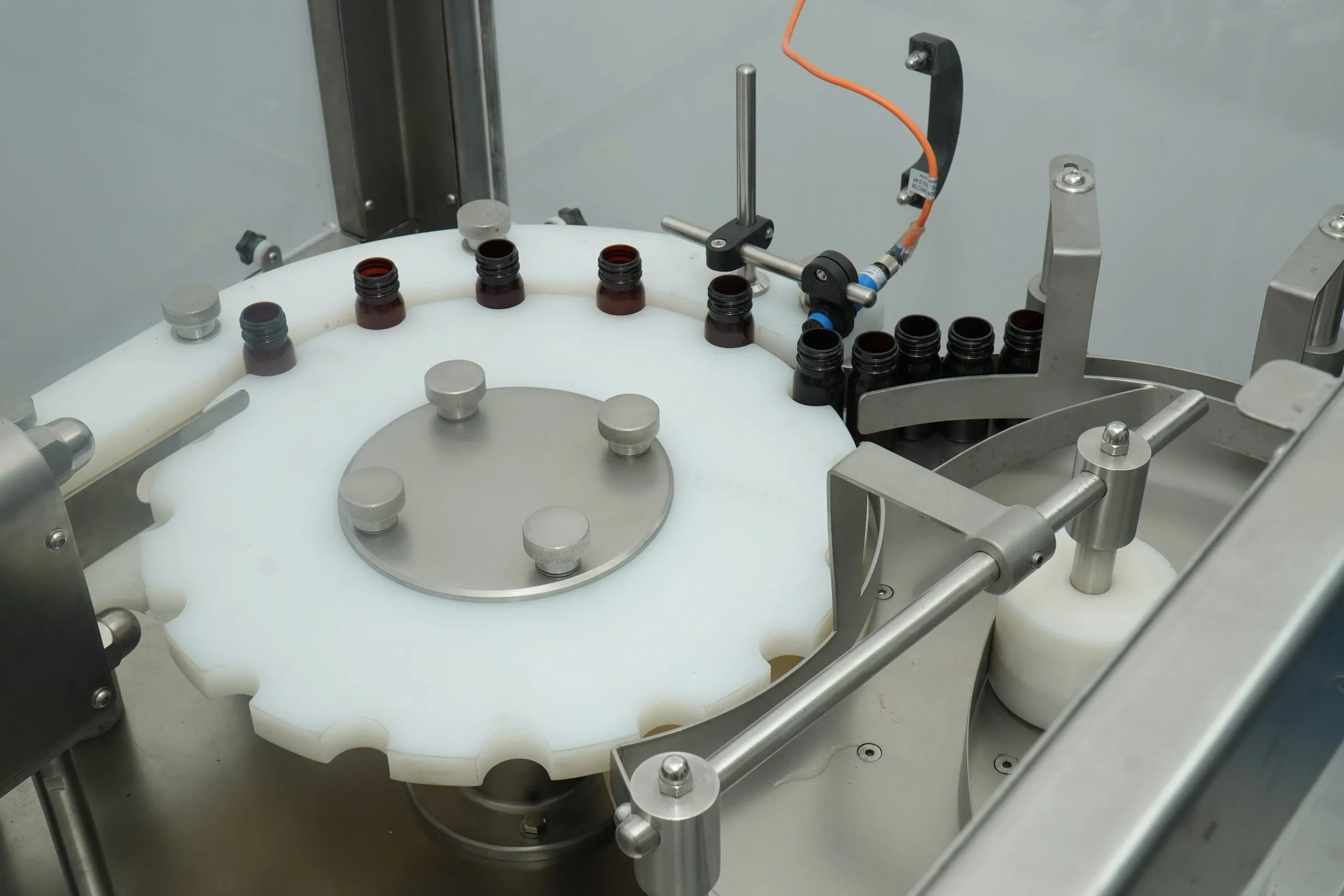

- Rotating tray (To feed the Bottles to the rotating star).

- Rotating star driven by a motor and speed reducer, the star feeds the Bottles to the Bottles rotating mechanism .

- First stage Bottles rotating mechanism.

- Heads for pumping clean compressed air into the Bottles.

- Second stage Bottles rotating mechanism.