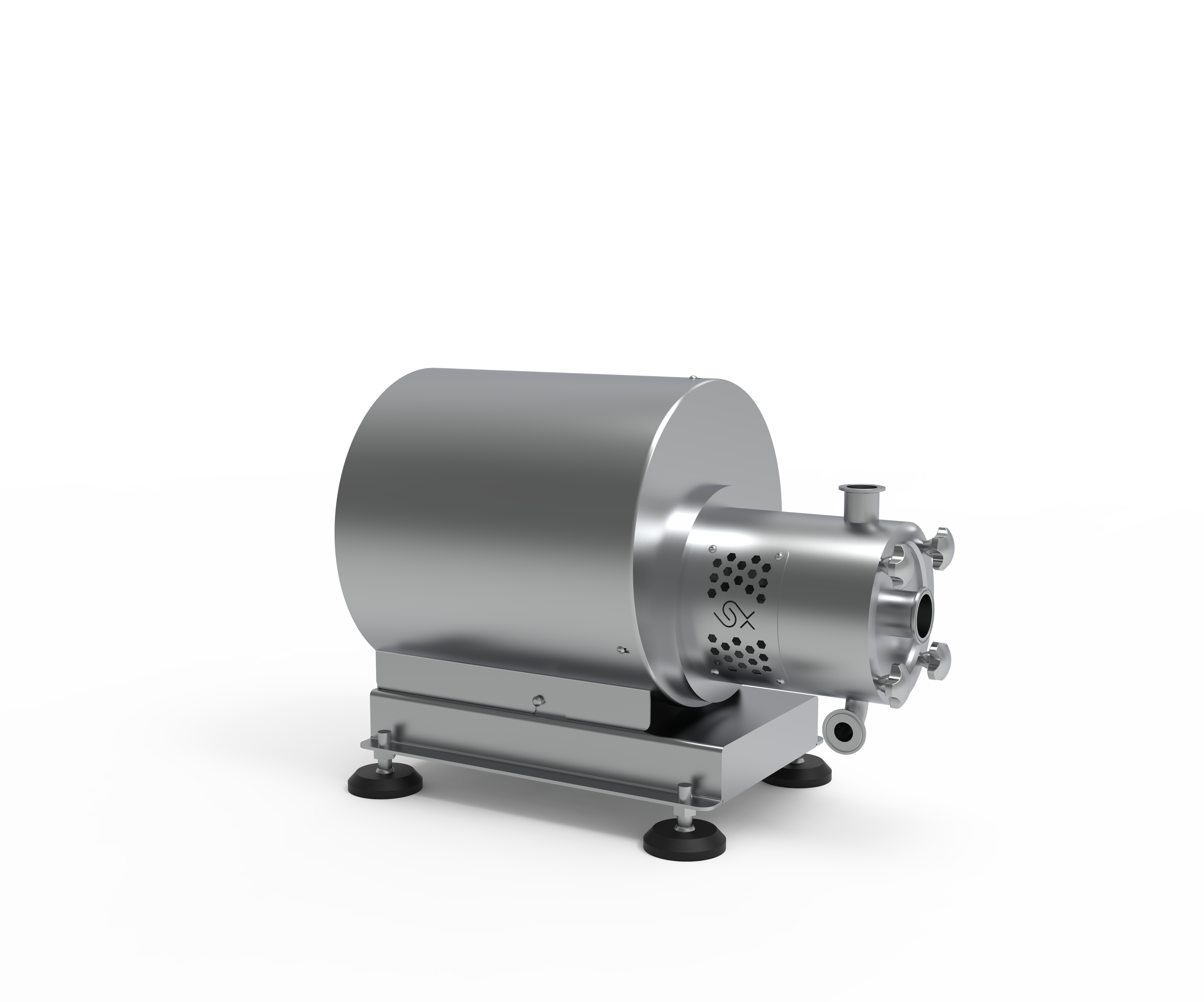

Description

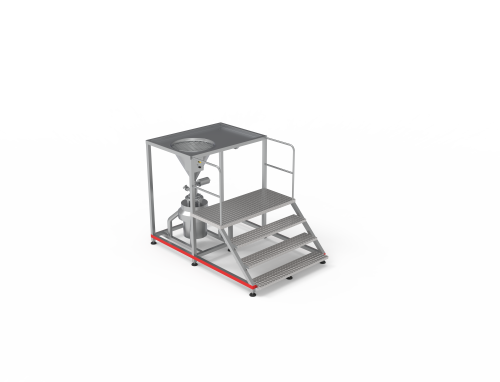

In Line Mixer’s main parts:

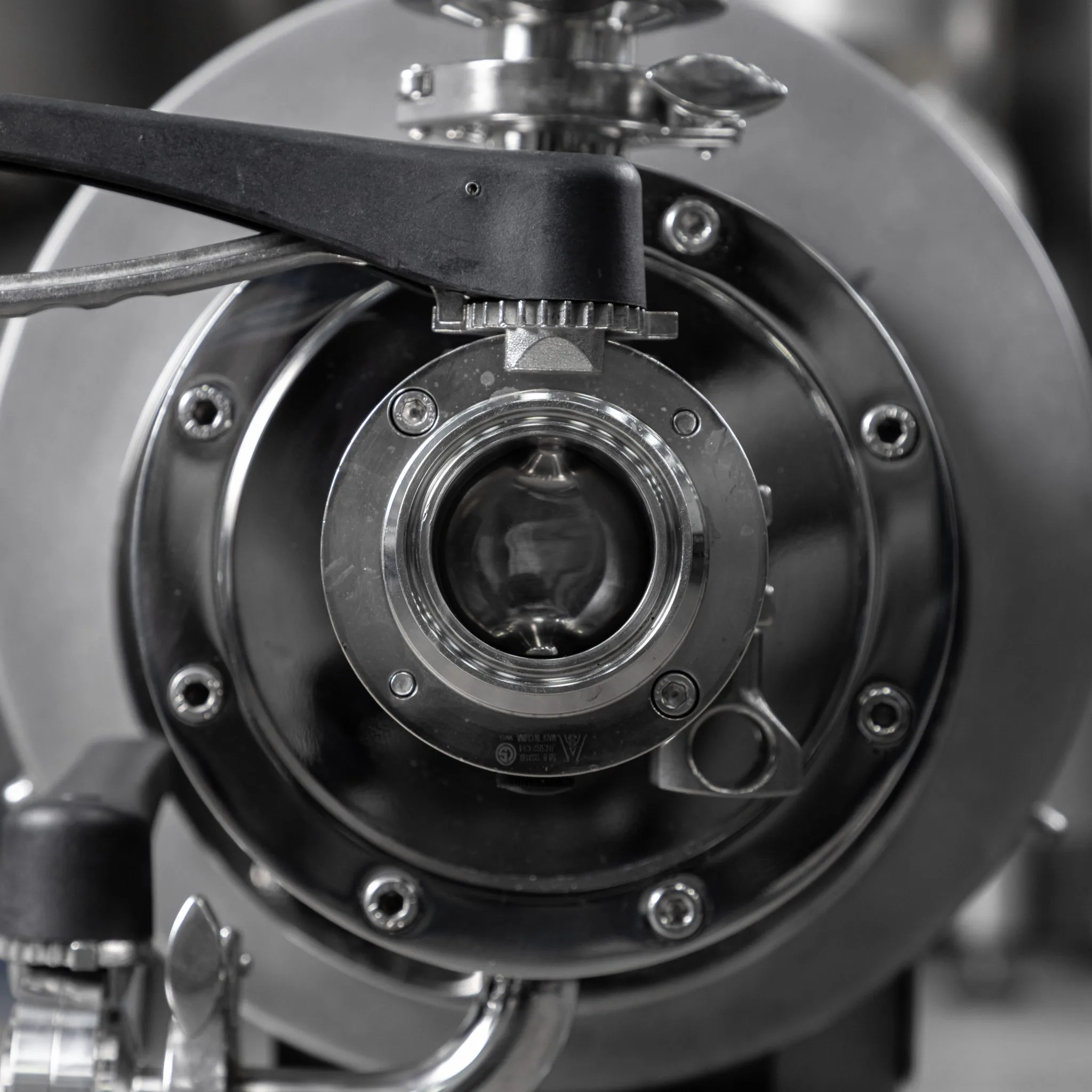

- Homogenization chamber

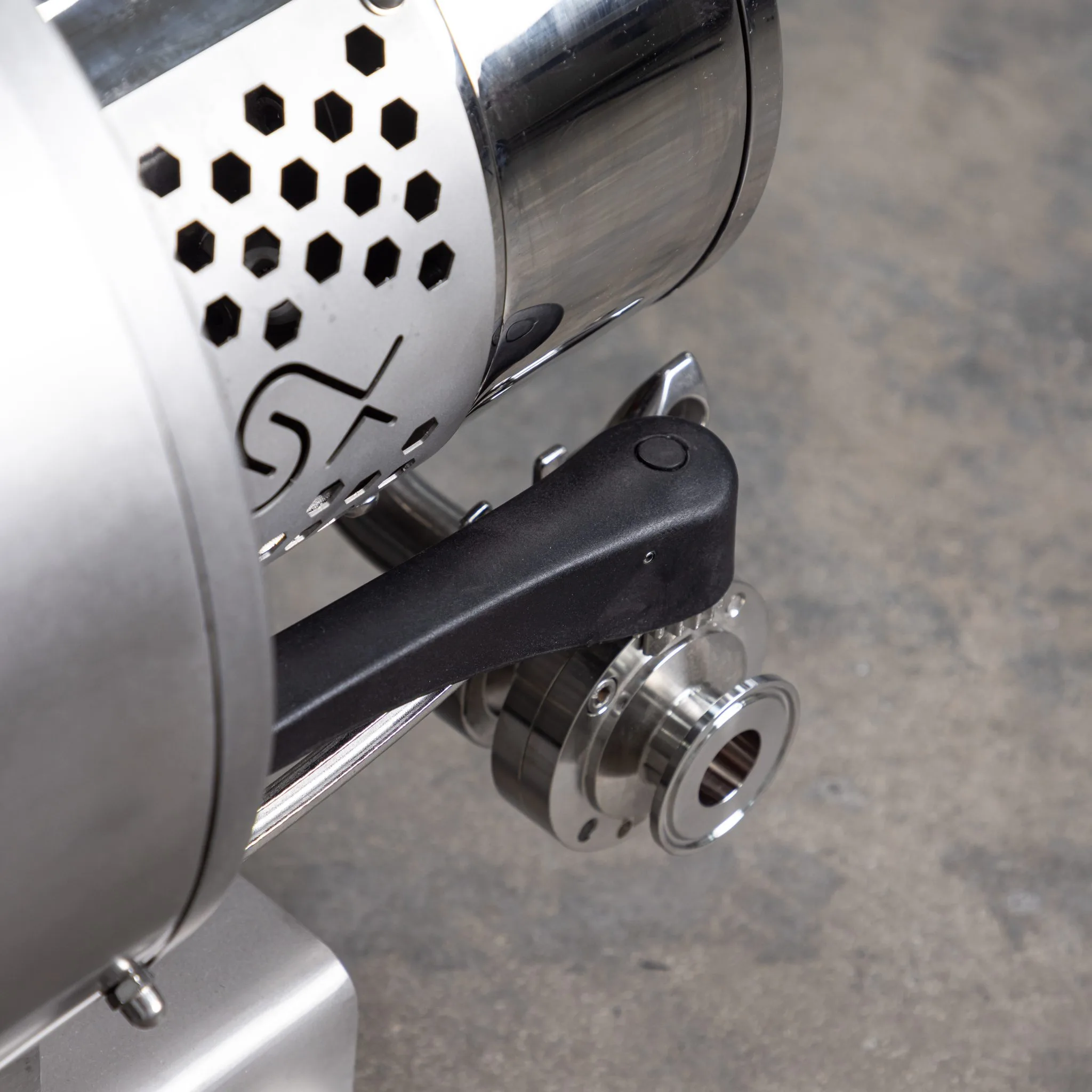

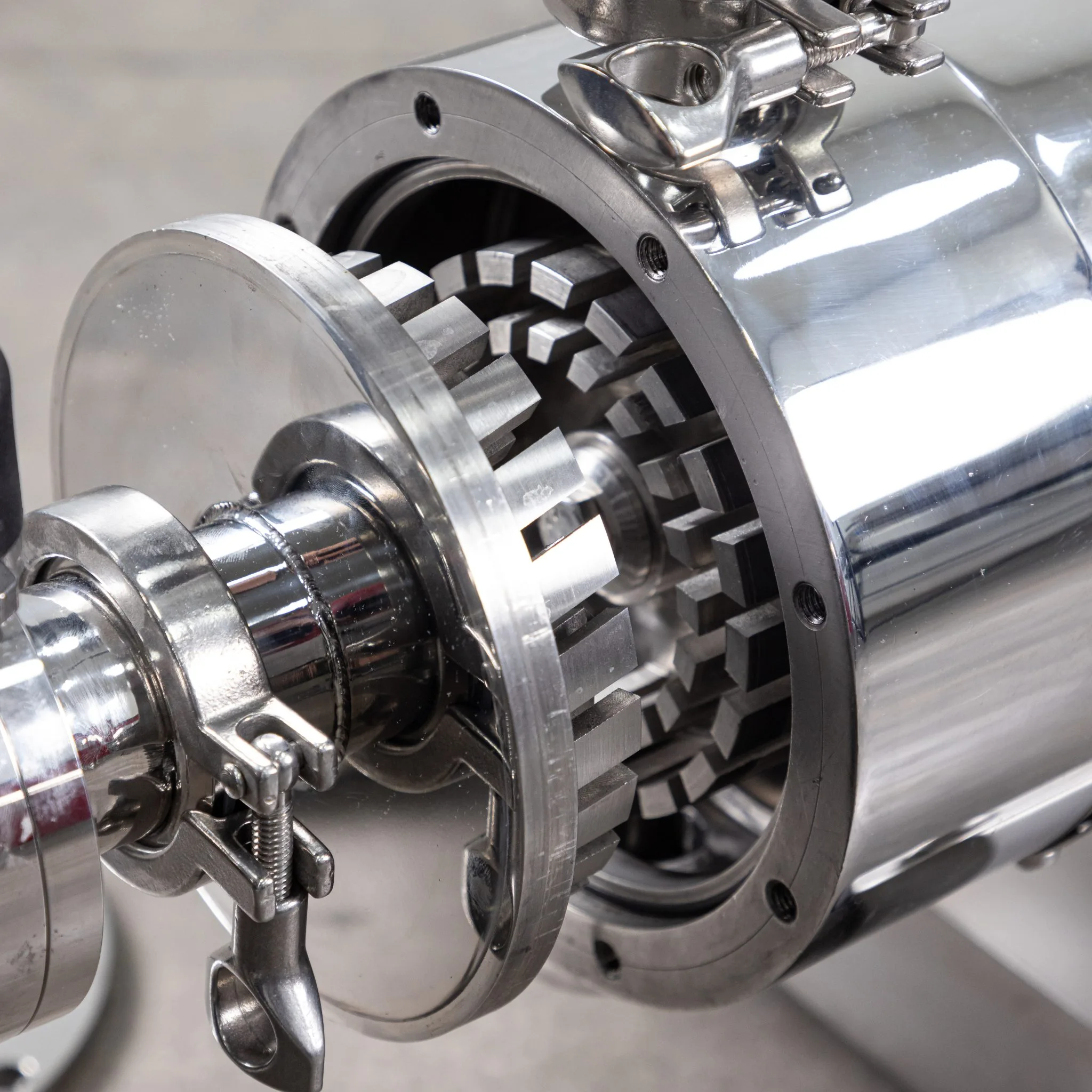

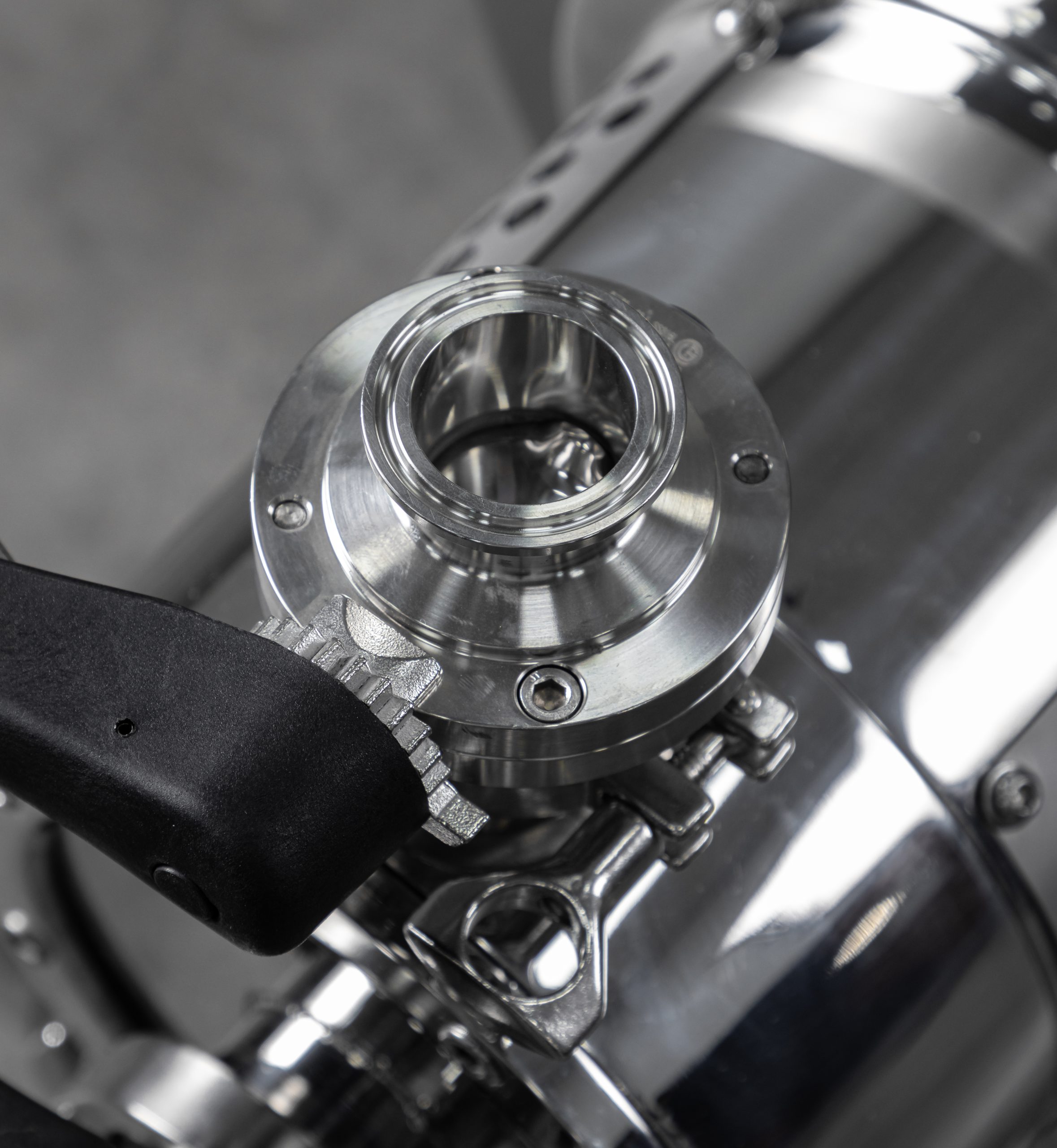

- The homogenizing head that consists of two parts:

-

- Rotor to perform the process of withdrawing and pushing the product.

- Stator to perform the process of homogenizing and softening.

- homogenizing Base that equipped with adjustable, fixed legs.