Description

• Easy investment through:

– The ability to switch from one product to another within a short time.

– Cleaning in place system CIP.

– Sterilization in place system SIP.

– Flexibility in calibrating and controlling all work parameters.

– Outstanding performance, easy to use and maintain.

• The equipment is highly efficient, flexible, and has low energy consumption.

• The necessary Documents such as installation, operation and maintenance manual.

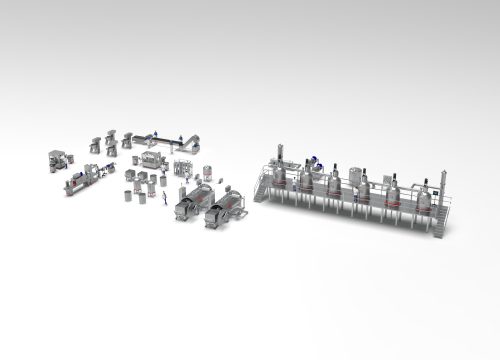

3D Model View

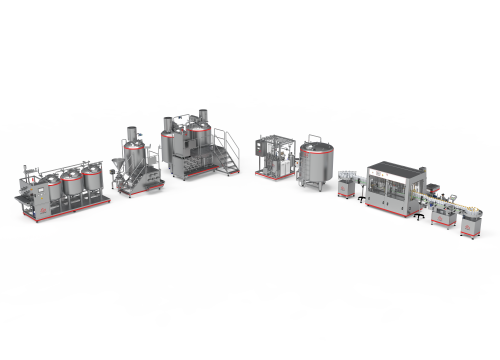

3D Model View