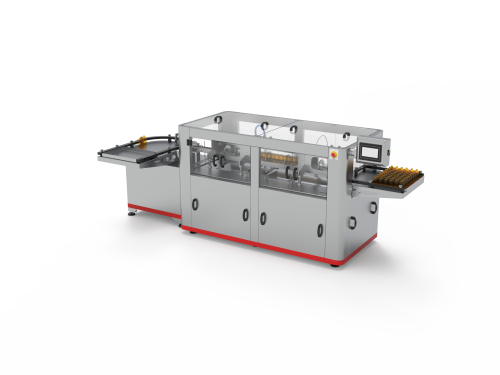

CIP Clean In Place unit-cGMP

- Is part of our wide range of Service equipment.

- The unit is used to wash preparation units, tanks and Loops in factories and production lines for the food, pharmaceutical, cosmetic & chemical industries.

- The unit consists of 3 Storage tanks, pumps, heat exchanger & all necessary pipes and connections.

- The unit is mounted on a stainless steel base.

- PLC & HMI control panel.

- All points welded by TIG & ORBITAL polished and treated.

- Product contact parts made of SS (316 L) and structure parts made of SS ( 304 ).

- Interior & exterior surface of the unite is a matt finishing .

Description

CIP unit’s main parts :

- Storage tank – single layer: For washing with pure water.

- Storage tank – single layer: For washing with acidic solution (ACID).

- Storage tank – single layer: For washing with alkaline solution (ALKALI).

- Plate heat exchanger for water heating, equipped with

- Inlet & outlet ports for heating medium (steam) and washing solution.

- Safety valve.

- Sanitary centrifugal pump to pump washing solutions into the LOOP and deliver the washing solutions to the machines and equipment.

- Stainless steel 316 LOOP.

Technical Data

- CIP unit featured by high efficiency, ease of use and low maintenance.

- It is designed and manufactured in accordance with international quality systems.

- It can be designed to meet exact customer requirements.

- Documentation and protocols ( DQ–IQ–OQ–FAT–SAT).

- After-sales services include maintenance operations and constant availability of spare parts.