Description

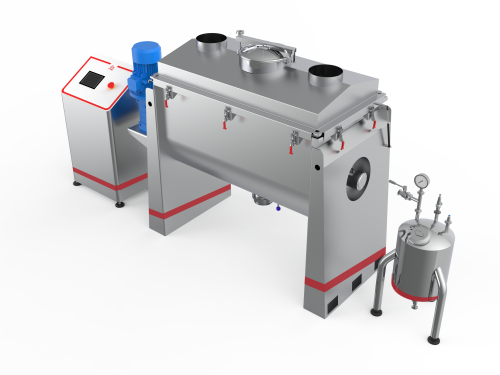

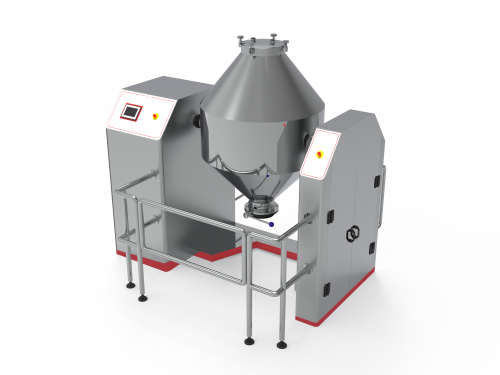

- The BIN Mixer is made of two parts :

BIN Mixing Chamber:

- A Manhole cover with arm.

- Discharge port with a manual operated butterfly valve

- Wheels for an easy movement.

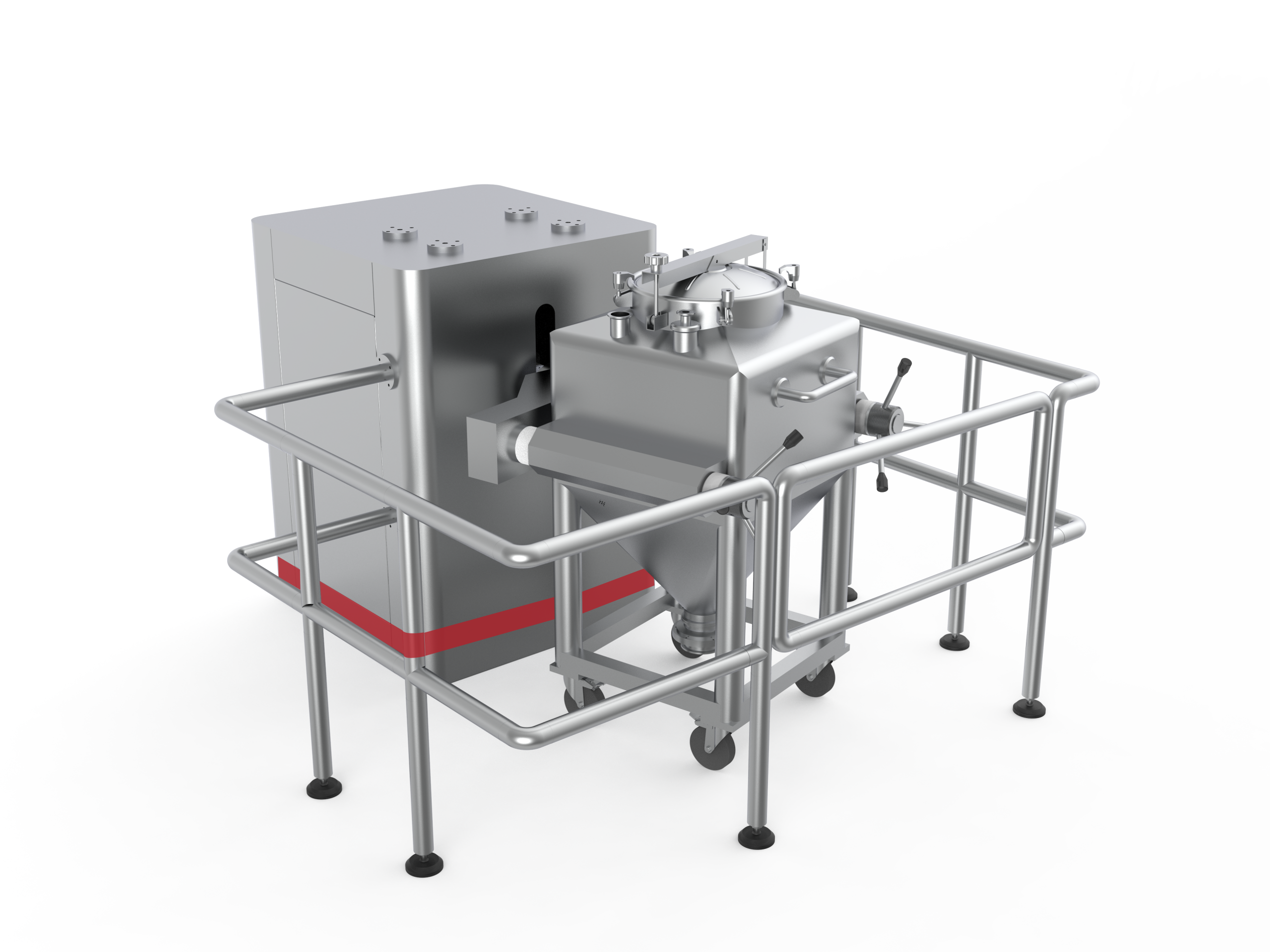

Mixing Mechanism for BIN Chamber:

- A mixing mechanism equipped with a motor and a hydraulic system to lift and rotate the chamber

- Sensor systems for controlling of start & stop of the Mixer.

- Guard rail with safety sensors to prevent approaching during work.

- Control panel to control all operation functions of the Mixer.