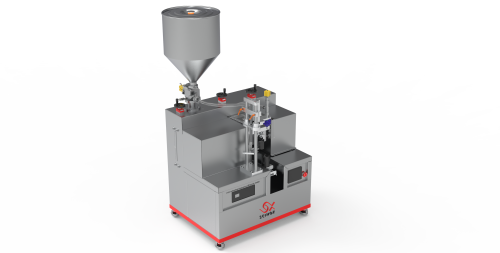

Description

Automatic tube filling machine’s working mechanism:

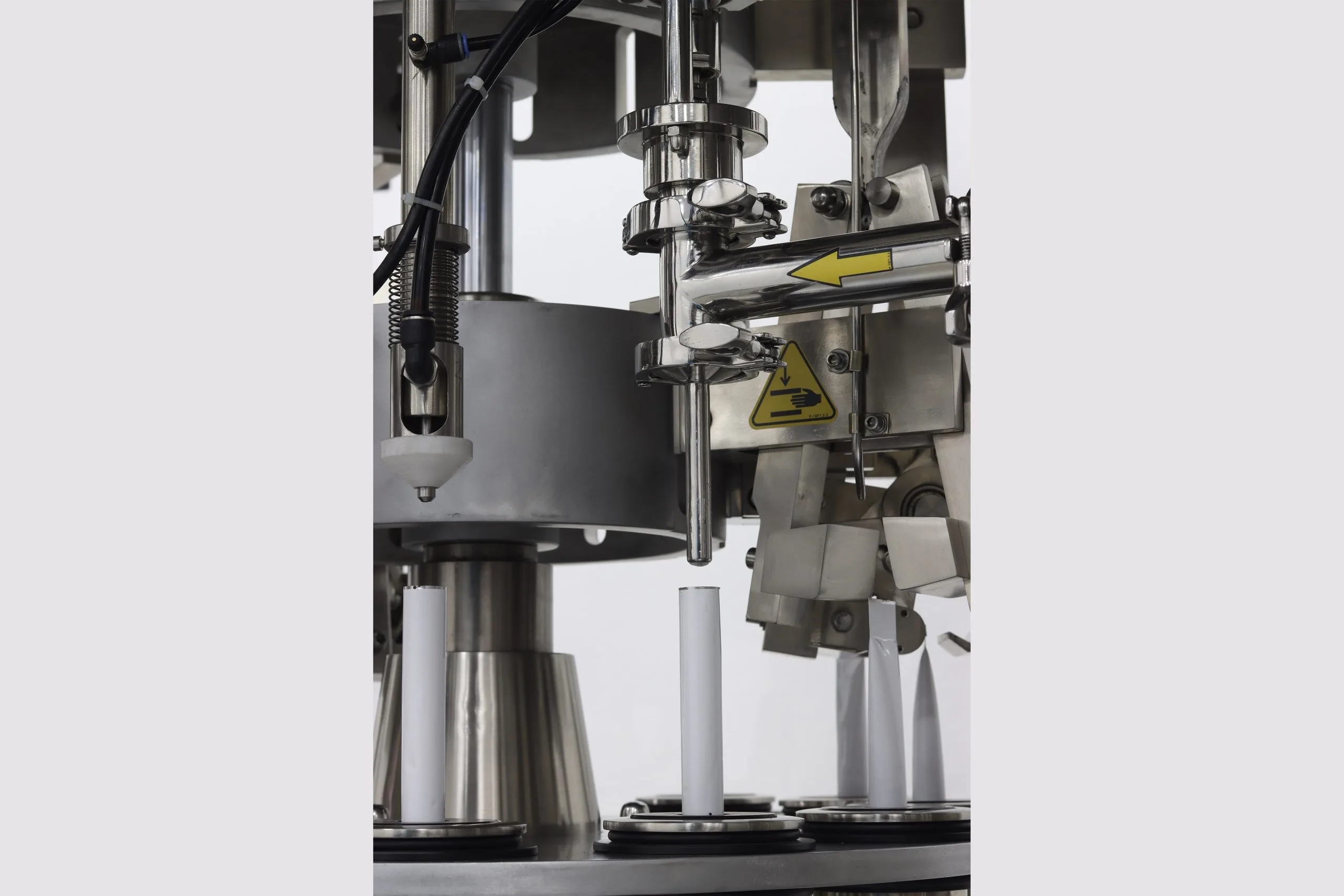

- Mechanism for automatically feeding tubes onto the rotating tray.

- A rotating tray with removable pucks.

- tube rotating mechanism in the correct direction.

- Nitrogen pumping nozzle.

- Double jacket hopper equipped with a mixing mechanism and a level sensor.

- Pressing mechanism.

- Multi-stage Folding mechanisms.

- Date setting mechanism.

- Tube ejecting mechanism .