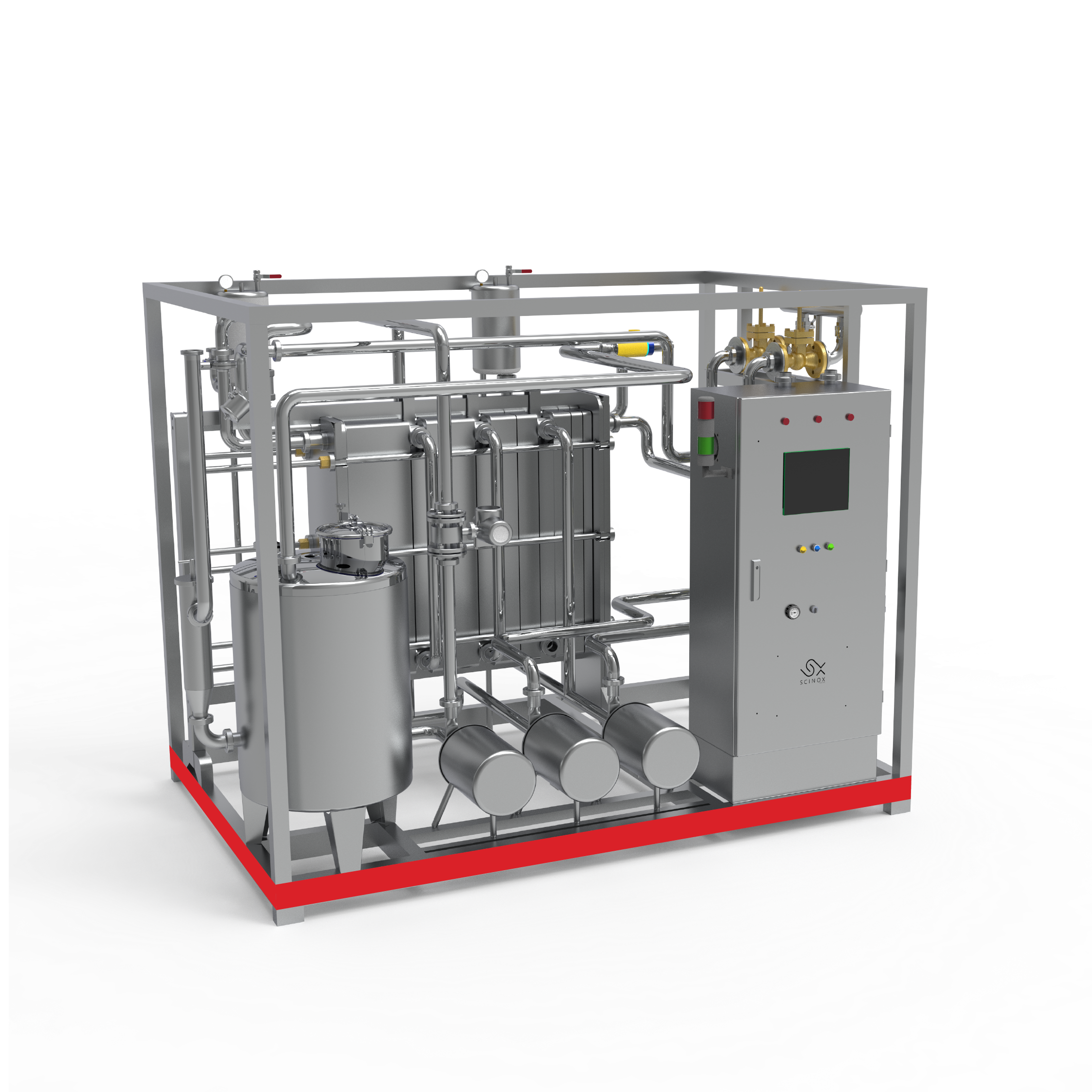

Description

Main parts:

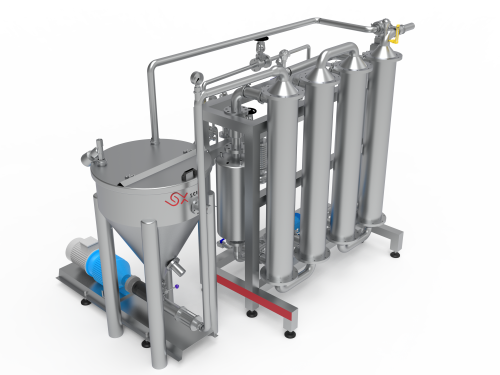

1. Balance tank (100) L: Equipped with a product level sensor to ensures a continuous and regular flow of product during work.

2. Centrifugal pump.

3. Flow meter.

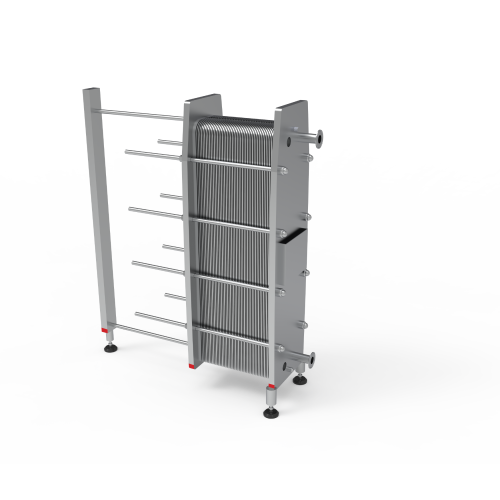

4. Plate heat exchanger operates at different temperatures depending on the type of final product.

5. Automatic Three-way valve: It is used to return the product to the balance tank if the necessary temperature is not achieved.

6. heating unit equipped with :

- Brazed plate heat exchanger.

- Acceleration pump.

- Automatic valve to control steam flow.

- The necessary protection equipment for all parts of the unit, including valves and pressure gauges.

7. Proportional valve.