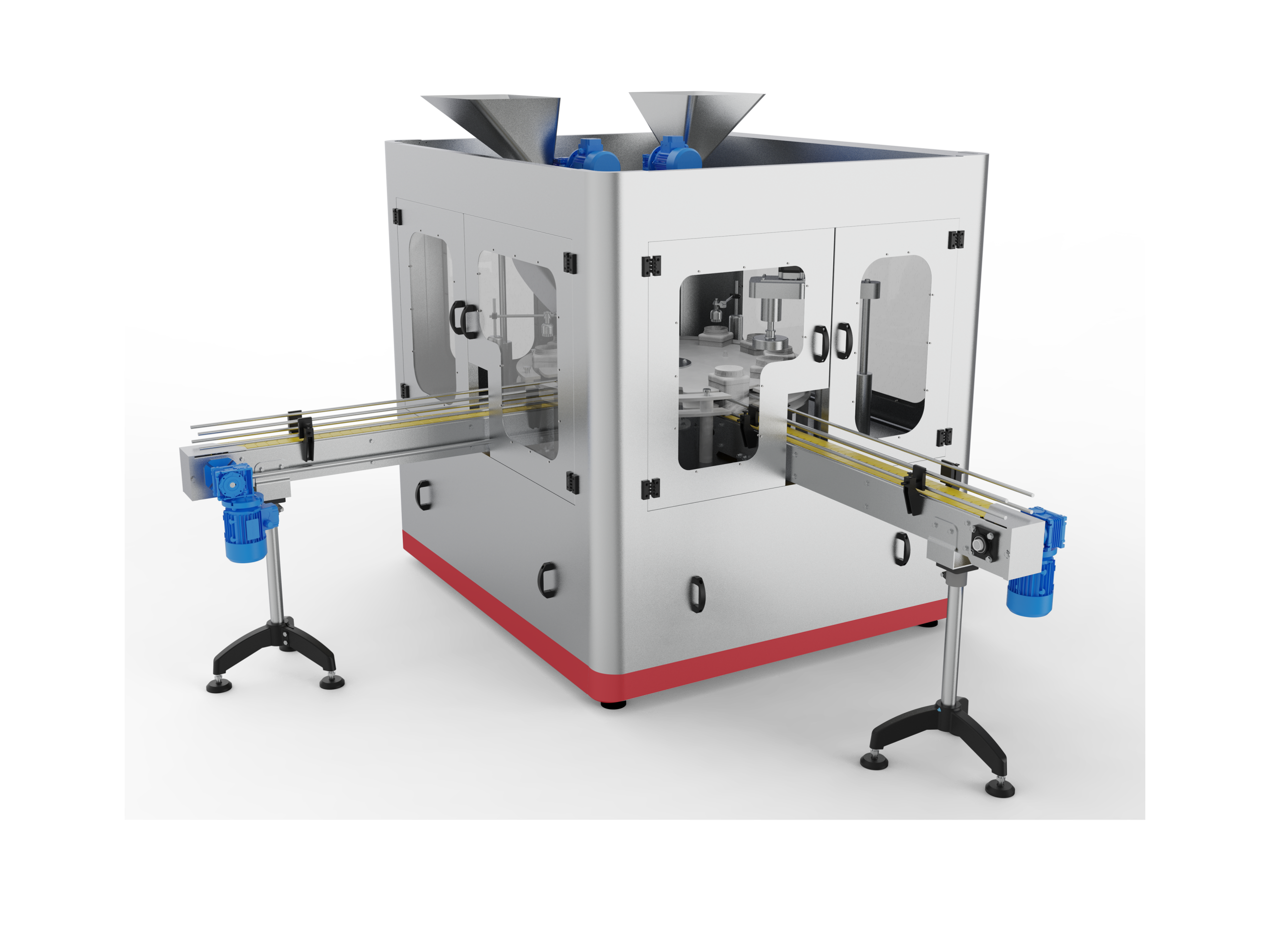

Auto-powder filling machine

- It’s a part of our wide range of powder filling machine .

- It is considered one of the basic equipment in the pharmaceutical industries.

- It’s used to fill dry powder (milk powder, powders, and the like) in a manner that is appropriate for the product, which leads to ensuring quality and achieving large productivity with high efficiency.

- The machine is suitable for multiple types of products and different shapes of Containers and can be adjusted to meet different capacities.

- All points welded by TIG & ORBITAL polished and treated.

- Product contact parts made of SS (316 L) and structure parts made of SS ( 304 ).

- Interior surface of machine is a mirror finishing and exterior surface is a mirror finishing.

Description

- Container entry and exit conveyor.

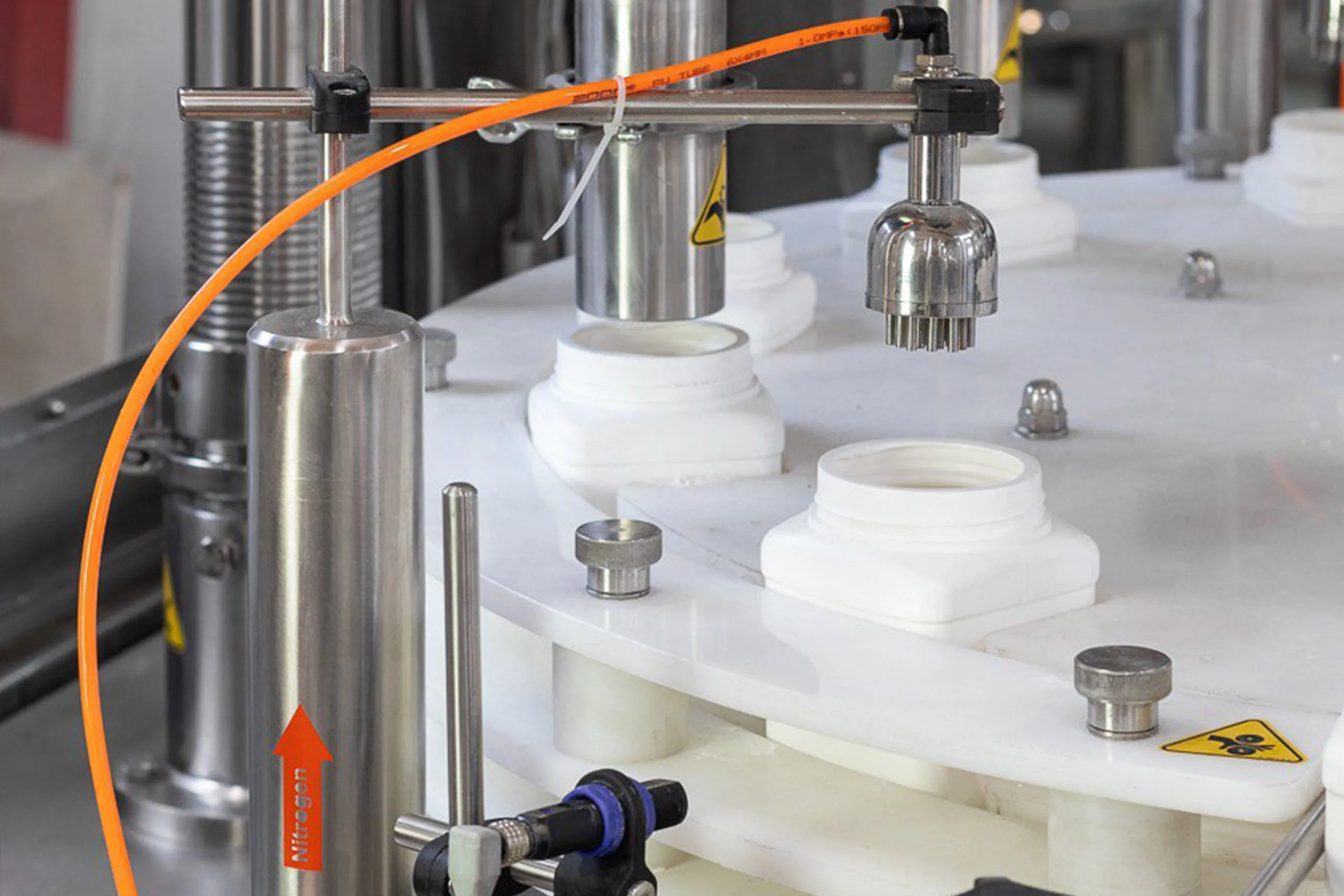

- Rotating star: used to move Containers under the filling heads.

- filling heads:

- The first head is volumetric.

- The second head is weighing connected to a weighing cell to accurately adjust the weight of the Container.

- conical funnels to ensure continuous and regular flow of the product during the filling process, equipped with:

- Level sensor.

- Side cleaning port.

- Feeding port via powder vacuum system.

- VENT filter to compensate for the air entering the funnel.

- Colleting basin to keep the workspace clean.

Technical Data

- powder filling machine featured by high efficiency, ease of use and low maintenance.

- It’s designed and manufactured in accordance with international quality systems.

- The production capacity varies depending on the type and density of the product.

- it can be designed to meet exact customer requirements.

- Documentation and protocols ( DQ–IQ–OQ–FAT–SAT).

- After-sales services include maintenance operations and constant availability of spare parts.