Description

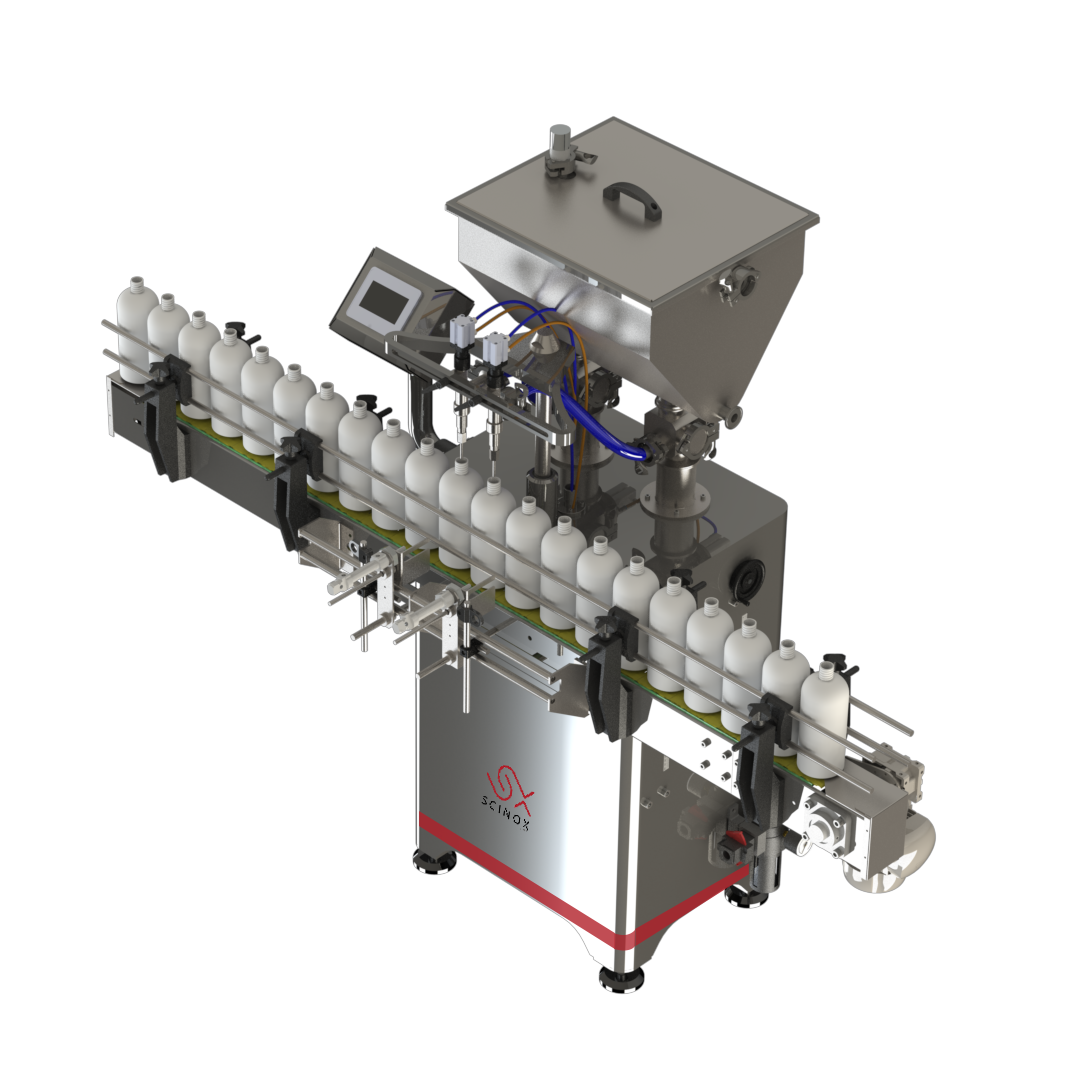

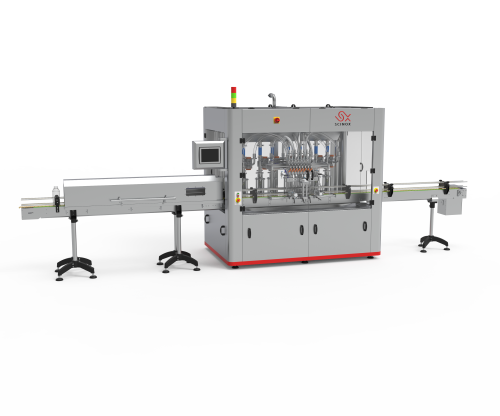

2H – Auto Liquid Filling Machine’s main parts :

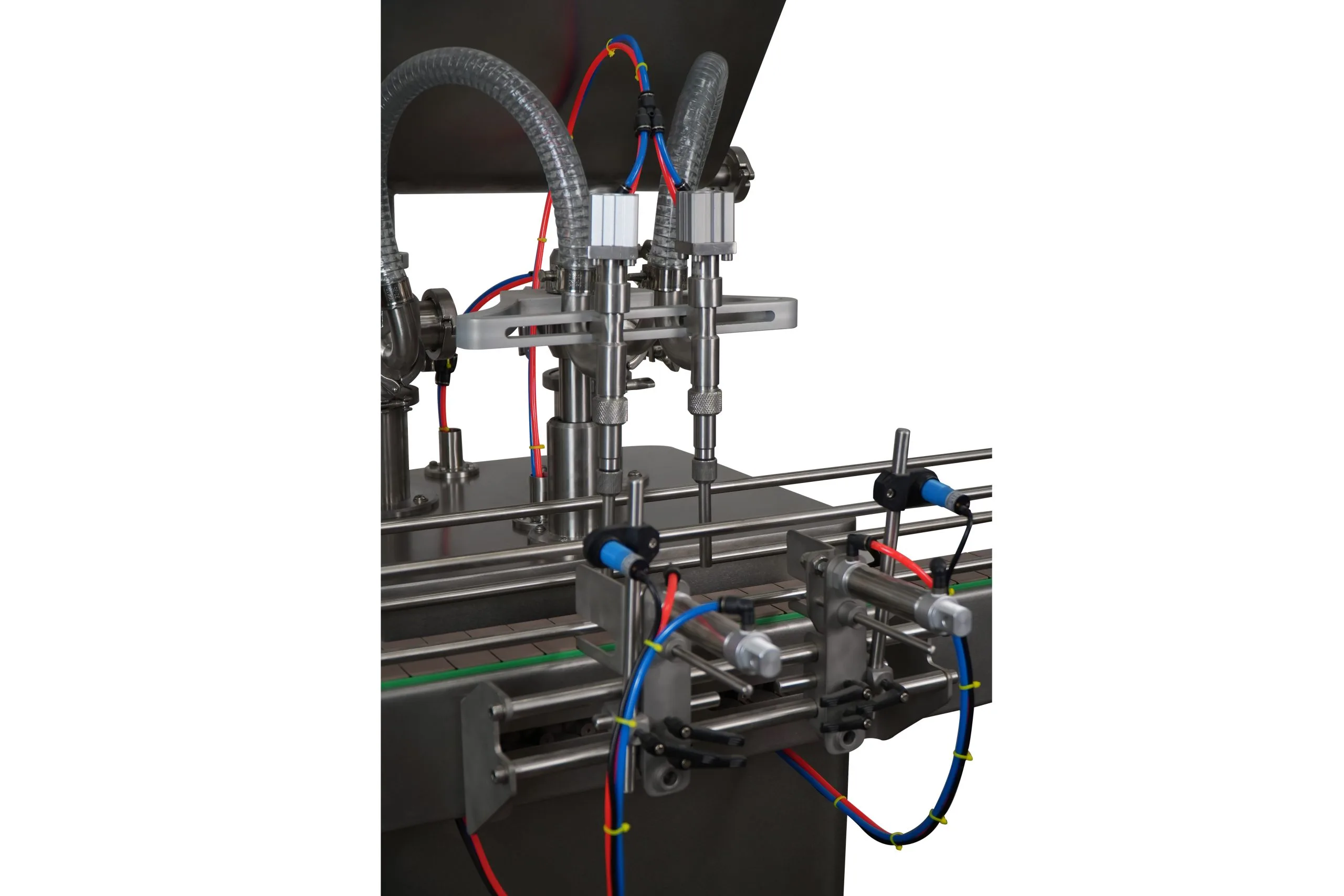

- Conveyor line Driven by a motor, speed reducer, equipped with a set of sensors and pistons for the entry and exit of bottles during the filling process.

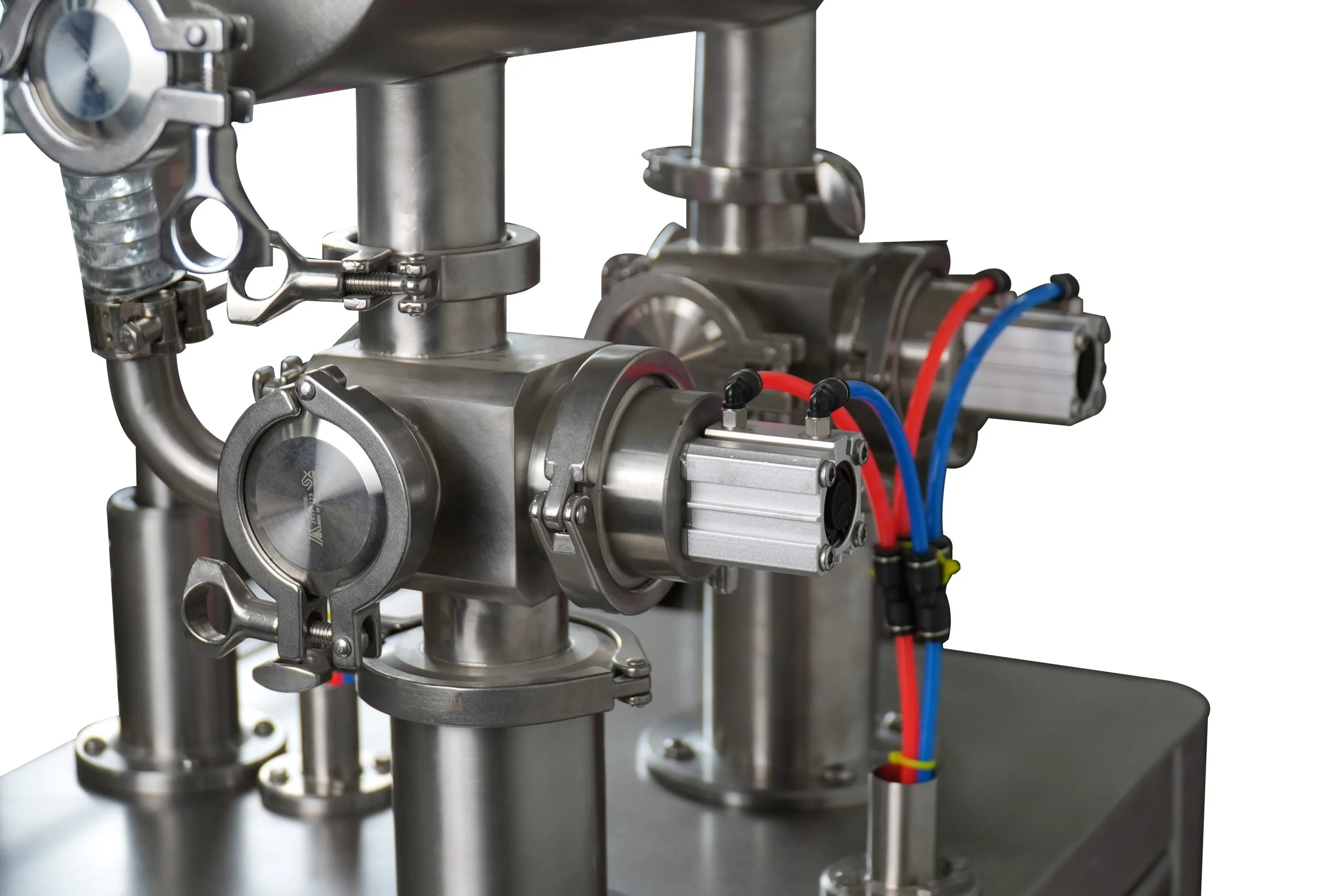

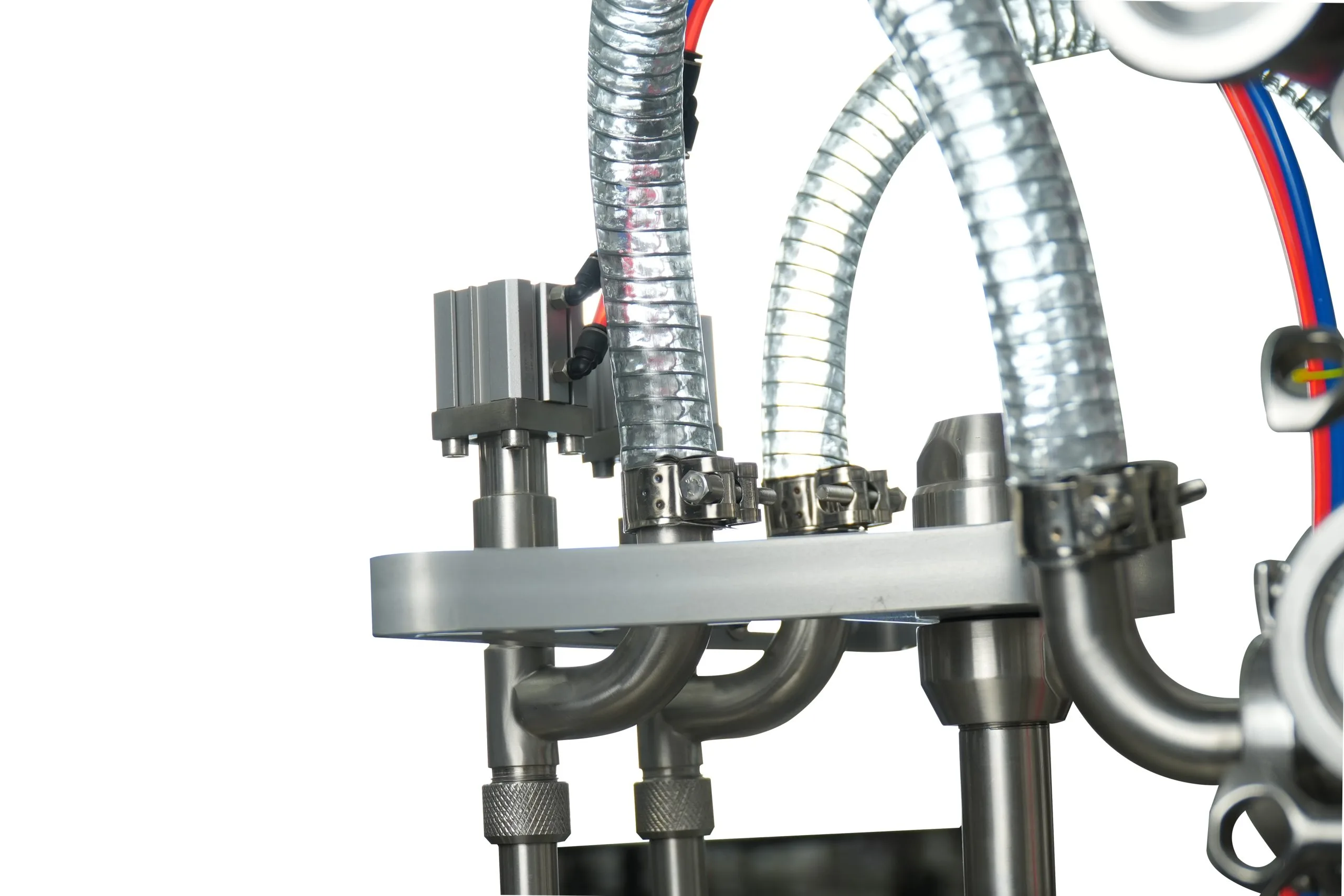

- Conical funnel equipped with:

- stainless steel lid.

- level sensor to ensure a continuous and regular flow during the filling process.

- Filling port.

- Drain for cleaning process.

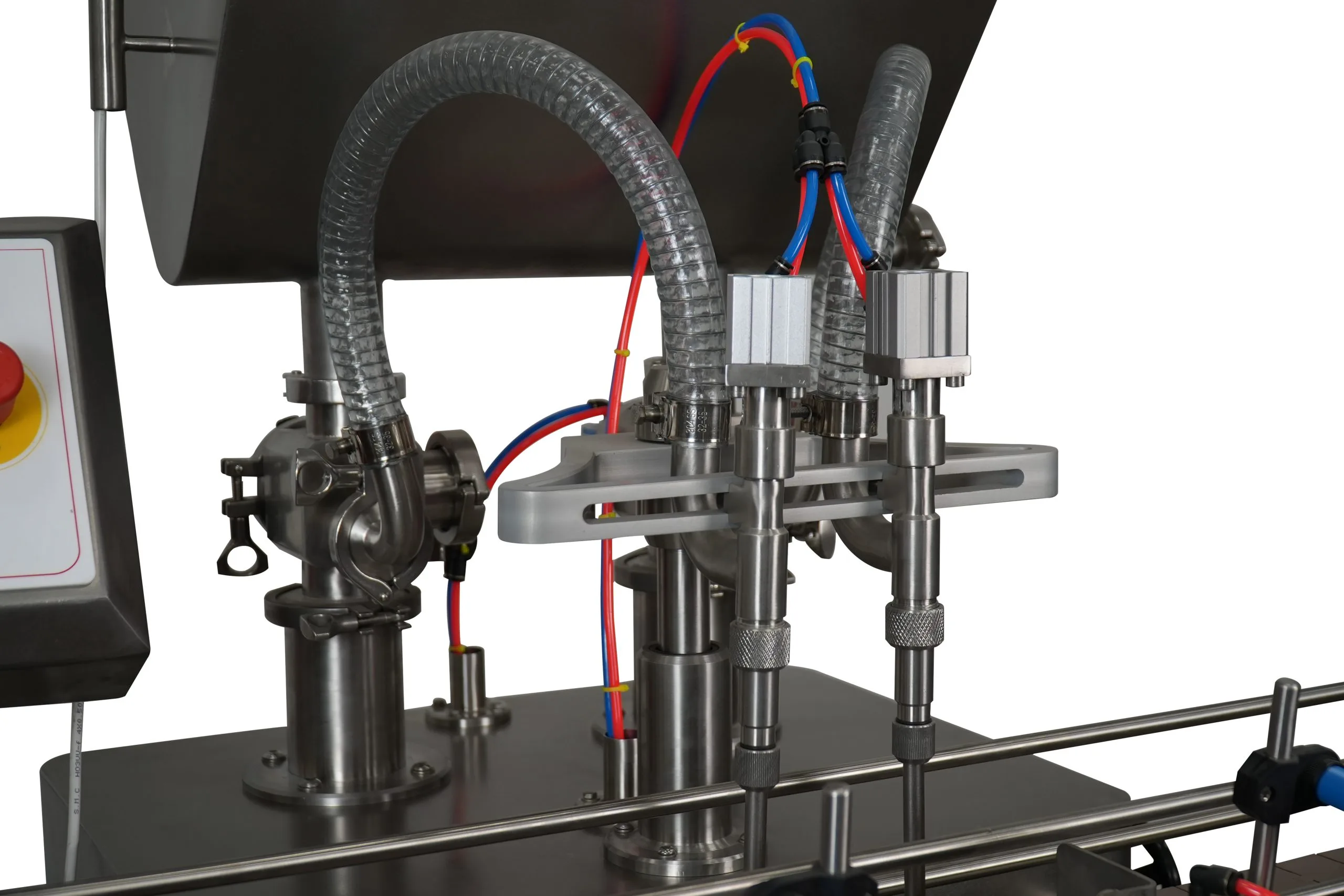

- 2 filling heads through which filling is done using a piston mechanism (pull/push).