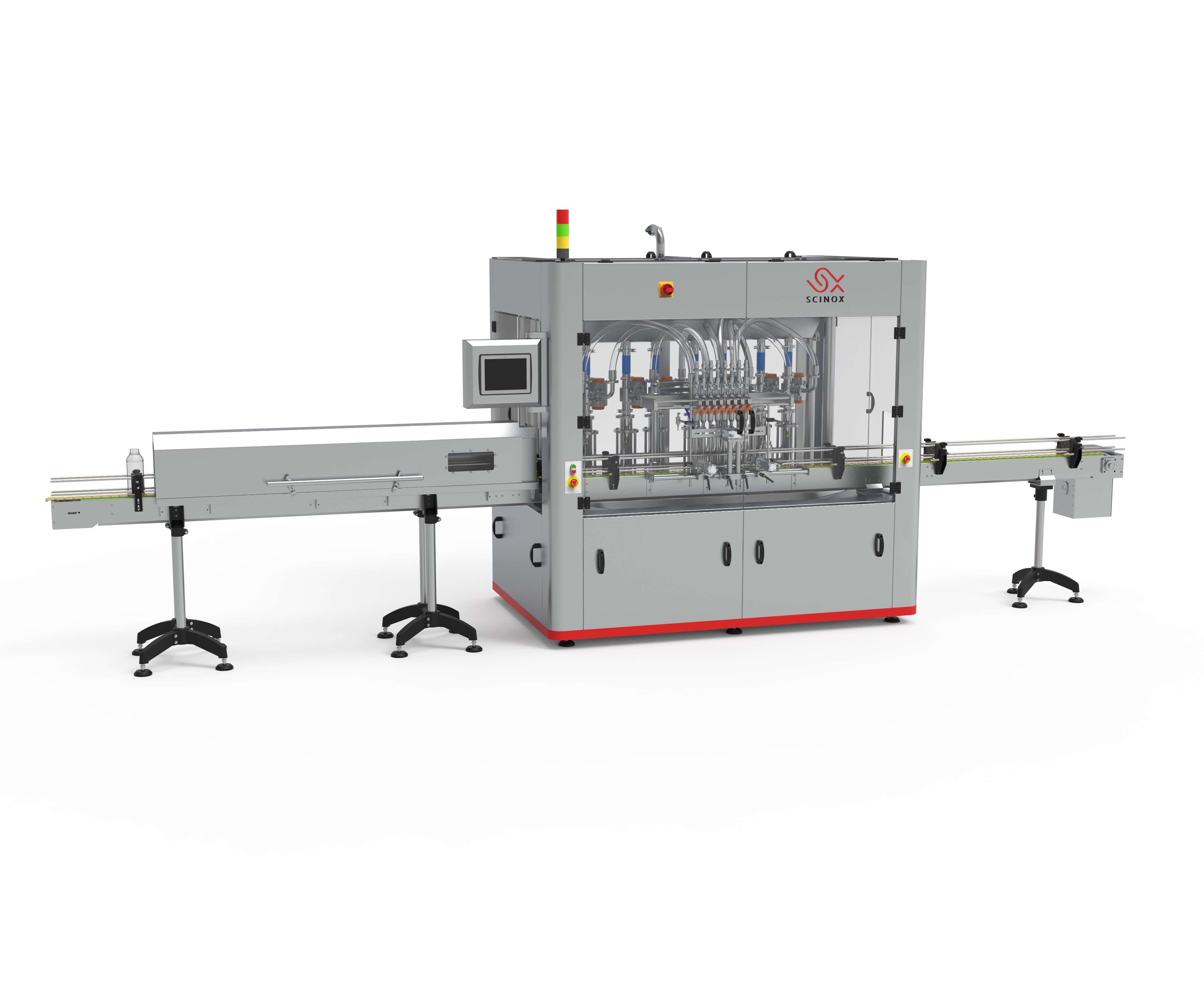

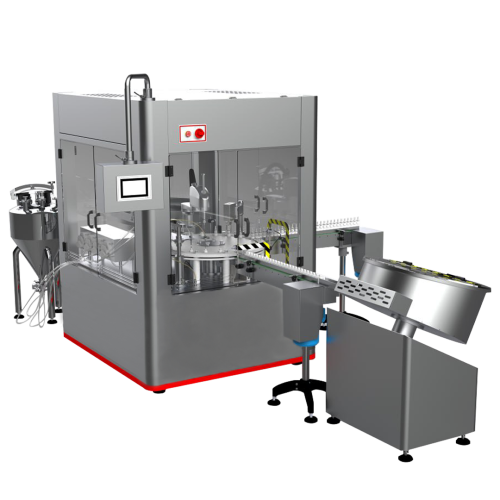

Description

Auto linear filling machine 8H-‘s main parts :

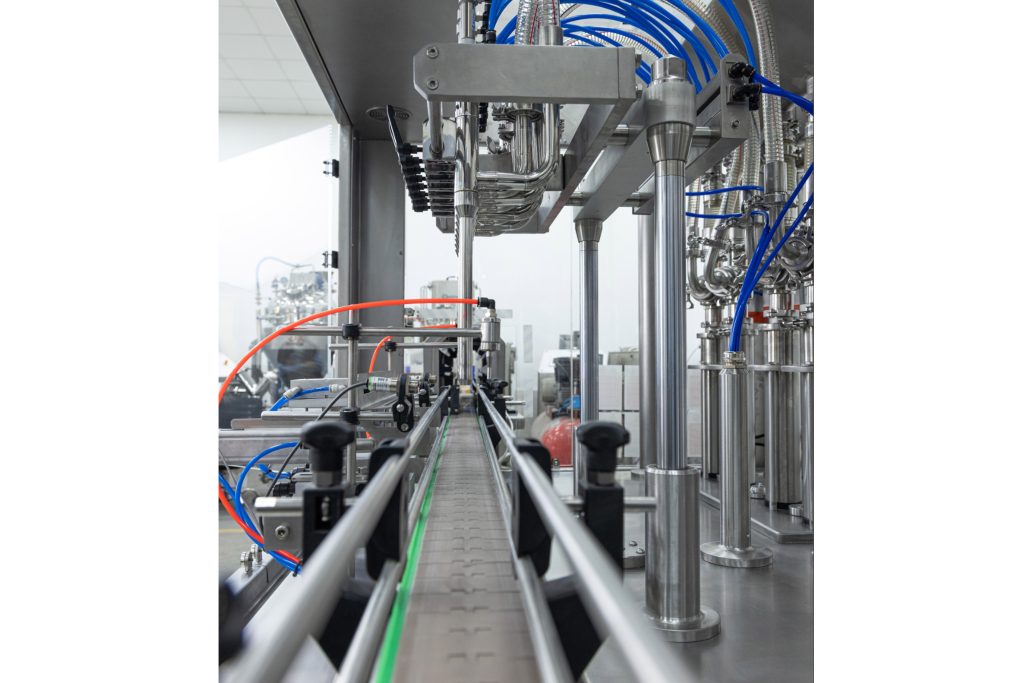

- Container Inlet Conveyor:

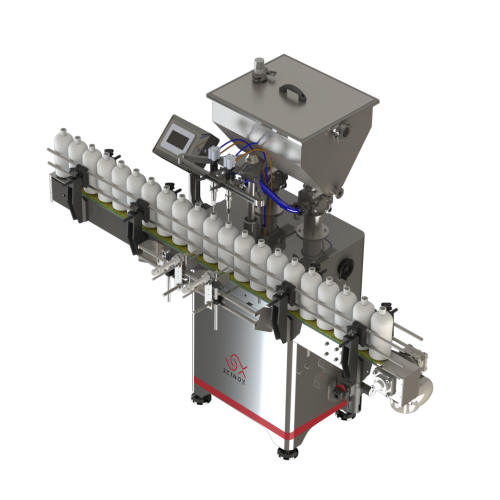

- A balance tank equipped with:

➢ A lid that can be opened and closed manually.

➢ A dedicated product inlet with a tube for distributing the product within the tank.

➢ A polarity level sensor.

➢ A drain outlet.

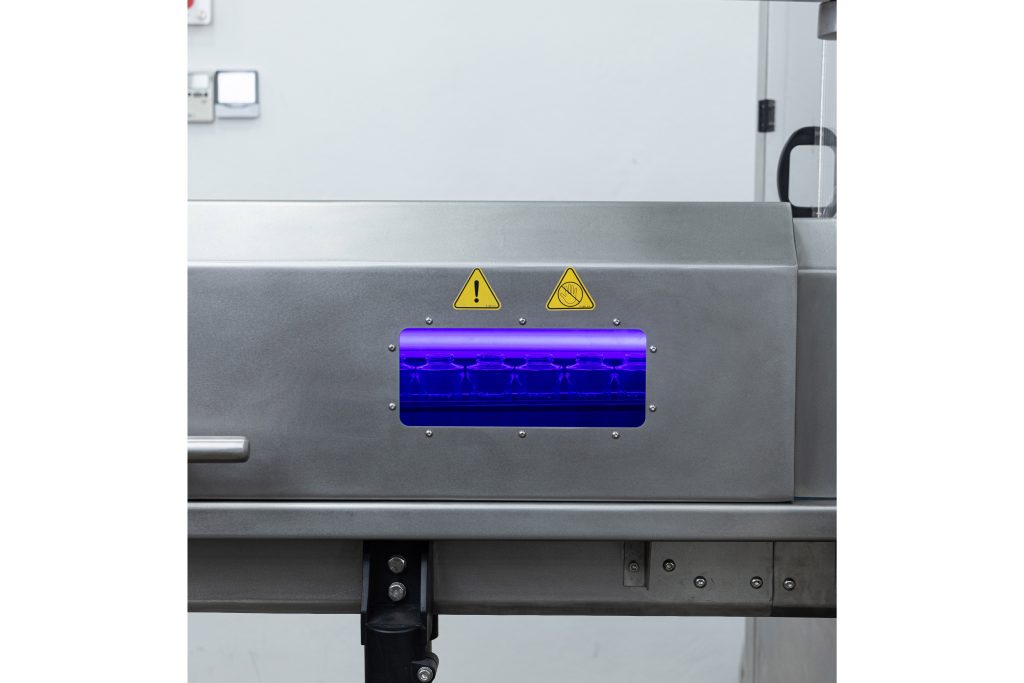

➢ Nozzles that connect with flexible connectors to the filling heads. - Nitrogen nozzle: This injects nitrogen into the container before filling.

- 8 filling heads: The entire system is driven by a servo motor that can be calibrated via the main control panel to ensure the quality and accuracy of the filling process in line with the machine’s workflow.

- Nitrogen nozzle: To inject nitrogen into the container after filling.

- Conveyor for Container Exit: The conveyor is motor-driven and has a speed reducer, as is the container inlet conveyor.